Chinese laser industry value tops 80 billion yuan

XIAHUI TANG and XIAO ZHU

After decades of development, China's laser industry has become a high-tech industry with industrial scale. Domestic laser enterprises are mainly distributed in the provinces of Hubei, Beijing, Jiangsu, Shanghai, and Shenzhen, with four laser industrial bases centered in them—the central China base, Bohai Region base, Yangtze River Delta base, and Pearl River Delta base, which have about 300 enterprises combined. Our estimate of the output value of the 2015 laser industry is nearly 80 billion yuan (about $12.2 billion), including 35 billion yuan (about $5.3 billion) from laser equipment and 45 billion yuan (about $6.8 billion) from the heavy, electronic, light, medical treatment, and military industries.

The major laser industry enterprises in Wuhan are HG Laser, Chutian Laser, Unity Laser, Golden Laser, and Raycus Laser. Shenzhen's major enterprises are Han's Laser, Sunshine Laser, GD Laser, and UW Laser; in Beijing, there is Daheng Optics and BIOET11; and in the east of China, there is Unity Prima and Eastern Laser. The eight Chinese-listed laser companies are HGTECH, Han's Laser, Golden Laser, Sunshine Laser, Castech, Siasun, Lida-OE, and Xin Nanyang.

Current situation in Hubei province

Wuhan, in China's Optical Valley, was the first to develop laser technology. After four generations of effort, it now has numerous system manufacturers and research institutions with powerful technical resources, and has application clients such as the large state-owned manufacturing enterprises like Wuhan Iron and Steel (Group) Corporation and Wuhan Heavy Duty Machine Tool Group Corporation.

The laser industry of Hubei has become an industry with strong competitive advantage. Hubei now has 200 laser-based enterprises, including 50 main ones.

The output value of the laser industry is nearly 35 billion yuan (about $5.3 billion), 25 billion ($3.8 billion) of which is from laser processing. With laser cutting, welding, precision machining, surface treatment equipment, and medical devices as the subject, Hubei has become the most important and intensive base of laser research, manufacturing, popularizing, and applications. The market share has come from many sectors, such as high-power industrial CO2 lasers, fiber lasers, laser cutters, and laser medical devices.

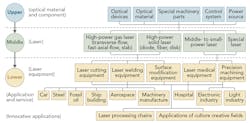

Hubei has a relatively complete laser industrial chain composed of laser material and matching components (upstream), lasers and matching devices (midstream), and laser equipment and application and service (downstream). The macroscopic structure of the industrial chain is shown in FIGURE 1.

The Hubei laser industry has formed a development pattern that centers on the East Lake National Innovation Demonstration Zone, and spreads into Hubei and central China. Wuhan, Ezhou, Xiaogan, Xiangyang, and Yichang are attractive places for laser enterprises.

Key enterprises

Hubei now has more than 200 laser-based enterprises, which are located in the East Lake National Innovation Demonstration Zone and Ezhou Development Zone. There are mainly domestic enterprises producing every process of the industrial chain, and its representatives are HG Tech, Chutian Laser, Golden Laser, Unity Laser, CO-Walking Laser, Raycus, Accelink, and Guide Infrared.

Wuhan Huagong Laser Engineering Co., Ltd. (HG Tech) is a joint-stock company that was transformed from the National Engineering Research Center for Laser Processing of Huagong University of Science & Technology (HUST) in 1997. The company has produced laser precision micromachining devices, high-power laser equipment devices, solid-state laser welding machines, laser marking machines, complete equipment of laser heat treatment equipment, and large laser texturing roll devices. The total output value in 2015 is about 1.2 billion yuan (about $182 million).

Wuhan Chutian Laser Group Co., Ltd. (Chutian Laser), founded in 1993, is a well-known laser equipment device manufacturer that focuses on three major industries: industrial laser, medical laser, and creative laser. The product of the industrial group covers lasers for welding, marking, cutting, drilling, heat treating, and trimming. The medical group is committed to serve comprehensive solutions for laser medicine and laser facial procedures for the global market.

Wuhan Unity Laser Co., Ltd. (Unity Laser) is a joint-stock/private enterprise founded in 1994 as the base of the Wuhan China Optical Valley. It is the largest enterprise producing complete high-power laser equipment devices and it is one of "the Big Three" of the Optical Valley, along with HG Tech and Chutian Laser.

Wuhan Raycus Fiber Laser Technologies Co., Ltd (Raycus) is the pioneering leading developer and manufacturer of high-power fiber lasers and components in China. Founded in 2007, Raycus has developed 10–100W Q-switched pulsed fiber lasers and 50W to 4kW continuous-wave (CW) fiber lasers. It is focused on China's industry, and the gross output value in 2015 is more than 0.4 billion yuan (about $60 million).

Wuhan Golden Laser Co., Ltd. (Golden Laser) is a listed enterprise committed to providing laser solutions for global customers. Its products include more than 100 different laser machines for cutting, engraving, marking, welding, embroidery, and other applications in various fields. Golden Laser has obtained many national patents and software copyrights for these products and technologies. The gross output value of 2015 is 0.2 billion yuan (about $30 million).

Wuhan Co-Walking Laser Tech. Co., Ltd. (Co-Walking) was established in 2006. This company is a manufacturer focused on high-power industrial fast-axial-flow CO2 laser technology. It was the first in China to develop the 4kW fast-axial-flow CO2 laser and the 7kW RF-excited fast-axial-flow CO2 laser, which reached the international advanced level. The company now produces the highest power level of CO2 lasers in China. The gross output value of 2015 is about 0.2 billion yuan (about $30 million).

Development status of industrial lasers

High-power fiber lasers. At Raycus, the Wuhan National Laboratory for Optoelectronics (WNLO), and Fiberway Technologies, improving the performance and output power of fiber lasers are main research interests. The target is to develop realistic 1–4kW fiber lasers, keep on developing high-power pump couplers, manufacture a high-power laser beam combiner by increasing fiber core diameter, produce 6kW fiber lasers, and develop a 10kW fiber laser. They also want to develop 100W pulsed fiber lasers, 1.5μm eye-safe, high-peak-power erbium-doped pulsed fiber lasers, and 2μm thulium-doped fiber lasers. These lasers have important applications in national defense, such as laser remote sensing and laser infrared techniques. The ultrafast fiber laser and high-power femtosecond pulsed fiber lasers that are developed by Wuhan Yangtze Soton Laser Co., Ltd. (Soton) provide ideal light sources for optical time-division multiplexing (OTDM) and for laser micromachining development.

High-power and high-beam-quality diode lasers. The target of Lingyun Photoelectronic System Co., Ltd. (Lingyun), HUST, and Raycus is to develop beam shaping, beam collimating, and fiber coupling of multi-array diode lasers, and study high-stability and high-power diode lasers to use as the pump source of fiber lasers or other applications. They plan to develop 1kW plastic welding diode lasers, a 4kW diode laser for surface modifying, and 2–3kW high-beam-quality diode lasers for cutting and welding.

High-power CO2 lasers. HUST has researched and developed a 1kW radial-polarization, fast-axial-flow CO2 laser with powers from 200W to 1kW. They have also developed a 3kW RF slab CO2 laser with output power from 100W to 3kW.

Frequency-shifted and ultrafast laser developments. HUST, Huaray Precision Laser Co., Ltd., and Soton have developed a series of nanosecond all-solid-state 10W ultraviolet (UV) lasers and a series of 10-50W picosecond lasers, with powers from 3 to 50W. Now, they are studying passive mode-locking, solid laser cavity, isolation design, and pulse select. The laser has single polarization output and can apply to light-emitting diode (LED) sapphire scribing.

High-power laser processing equipment. Large laser processing equipment based on high-power (2–10kW) industrial lasers is developed for applications in the steel, oil, metallurgy, car, shipbuilding, and aerospace industries, among others. Technologies include high-power laser cutting, cladding, heat treating, and welding. Wuhan now has more than 10 laser cutting factories producing middle- to high-power, small- to large-format, and rigid- to flexible-system equipment.

Lasers mainly for automotive and welding robots. Wuhan Farley Laserlab Cutting Welding System Engineering Co., Ltd. (Farley), Penta-Chutian Laser (Wuhan) Co., Ltd. (Penta-Chutian), HG-Tech, and HUST apply robot laser machining systems for the automotive industry. Remote scanning and welding technology makes full use of single-side and contactless laser welding technology, and also combines these advantages with high-speed scanning lenses so that welding time is greatly shortened.

The development of vehicle door and car floor laser remote scanning and welding systems uses high-power fiber or disk lasers linked to a control system for a 6-axis robot and 3-axis oscillating mirror for production lines with vehicle floorboard remote scanning and welding, as well as vehicle door remote scanning. Also employed are remote scanning, welding, and quality inspection technologies to meet the need for efficient position of 3D vehicle body welding, and to develop large-format, high-speed laser cutting systems for thick steel.

They are also solving technical problems in high-power, large-format, multi-drill-on-the-fly (DoF), and flying-optics CO2 laser cutting systems, including optical transmission (beam collimation, aplanatic, focus, light stability); manufacturing technology of long-cantilever, knuckle-arm, linear-motor-drive high-speed cutting machines; control systems; advanced software technologies; and system integration technology. This leads to domestic high-end laser cutting devices to make breakthroughs in ship, steel, construction machine, and military project applications, and to replace imported systems.

Fiber laser cutting machines are now being vigorously developed and mainly applied in sheet metal cutting, with applications in aerospace equipment, shipbuilding, instrumentation, mechanical and electrical products, and car making. The focus now is on developing online laser welding devices for metal strip used for car body and high-power laser welding systems for aerospace applications.

Hybrid welding systems for aerospace application. HG-Tech, HUST, Penta-Chutian, and Farley are now researching technology for laser welding materials such as aluminum (Al), manganese (Mg), copper (Cu), and titanium (Ti) alloys. They are studying filler wire material of high-strength Al alloy, and trying to make progress in laser welding technology for high-strength Al alloy plate with thicknesses of 10–20mm. They are also studying high-power fiber laser welding of nonferrous and mid-thick plate, and techniques in MIG hybrid welding and filler wire hybrid welding.

High-power diode laser processing. HG Laser and Unity Laser are researching integrated intelligent diode laser surface hardening and remanufacturing systems to verify the intelligent control of distance, temperature, and trace and treatment effect. This can be used in heat treating and repairing of big mechanical components for automotive panel dies, mine machines, coal machines, and petrochemical machines and generating units (FIGURE 2).

Precision micromachining systems for the electronic industry. HG Tech, Lingyun, and Sunic Laser Co., Ltd. are developing low-average-power industrial laser precision machining equipment with high repetition frequency, high peak power, short wavelength, and short pulse width for laser precision adjustment systems, laser precision repairing systems for liquid-crystal displays (LCDs), laser precision repairing systems for printed circuit boards (PCBs), laser silicon-chip cut scribing systems, UV laser LED sapphire substrate epitaxial wafer scribing, and some key technologies and equipment such as precision gratings, surface-mount technology (SMT) stencils, flexible printed circuit (FPC) cutting, hole-drilling technique (HDT), laser micromarking, and PCB outlet welding.

The development of private laser manufacturing equipment for 3D products and applications of laser wire stripping, welding, cutting, and tin soldering has greatly promoted the replacement of manufacturing techniques, offering higher performance, high intelligence, and high integration. They also developed necessary techniques for advanced electronic product manufacturing. They make use of laser precision techniques to improve the efficiency and lifetime of LEDs by drilling a micro-hole under the LED and making a direct channel for hot air to flow to the radiator. Scribing, marking, and drilling of solar batteries are also important applications for laser precision machining.

The laser precision soft brazing systems have 50–1000μm spot size, minimum spot size <0.1mm, single spot welding speed ≤20ms, and positional accuracy <0.01mm to meet the needs of applications like chip ball mounting, PCB soldering, connector manufacturing, and special spot soldering.

The flexible PCB laser cutting systems offer speeds of ≤4m/s, manufacturing accuracy of ±20μm, and process line speed of ≤7000mm/s.

The picosecond laser and strontium laser core technologies applied in touch-panel cutting and ITO film fabricating deliver <0.05mm/s cutting speed.

Perspectives on development

China will keep developing the laser industry with focus on three main directions: new core lasers, high-end laser manufacturing equipment, and laser machining. Development of industrial technology innovative systems will make breakthroughs in key areas. The goal is to make Hubei's output value of the laser industry chain reach 100 billion yuan ($15 billion) with an average growth rate per annum of more than 25%. To do this, we will build a "domestic topping and foreign knowing" laser industry base, and form a special industrial cluster that will be a world first in fractionized field.

We will use leading enterprises as a vehicle to improve production of laser cutting equipment; form a high-power industrial chain; push the applications and high-end development of laser welding devices; encourage the crossover of laser 3D printing, laser remanufacturing devices, and traditional manufacturing devices; and achieve the industrialization of precision laser micromachining systems.

High-power and high-beam-quality diode lasers will be the main source of laser welding, remanufacturing, and 3D printing. Middle- and small-power, high-beam-quality diode lasers will be the main light source of laser medicine, and UV, picosecond, and femtosecond lasers will be the main light source in precision micromachining. Diode laser precision micromachining will have a huge business opportunity in future China.

Prof.XIAHUI ANG([email protected]) andProf.XIAO ZHUare with the National Engineering Research Center for Laser Processing of Huazhong University of Science and Technology, Huazhong, China, www.hust.edu.cn.