The capabilities of remote optics must be weighed against product design restrictions

Geert Verhaeghe

More Industrial Laser Solutions Articles |

Laser-GMA hybrid joining of thick high-strength steels |

The key drivers for automotive seat production are lightweight and low-cost structures on a global vehicle platform. The requirement for reduced CO2 emissions through weight reductions is driving the need for joining thinner and higher-strength steels and/or multi-material structures. However, the most competitive low-cost structure can only be achieved by adopting a modular manufacturing approach that can be tailored to a customer’s individual needs. To achieve these competing requirements, conventional processes such as spot and arc welding are being pushed to the limits, and in some cases have already reached their full potential. Even for a relatively young process such as laser welding, the pressure is on to reproducibly deliver quality at ever higher productivity. This is the reason Faurecia continuously investigates how laser technology can be used in a smarter way — and why a major shift took place recently to produce work pieces with remote laser welding (instead of using the conventional fixed optics), which offers flexibility and productivity in an environment where thinner and increasingly higher strength steels are part of the seat structure design.

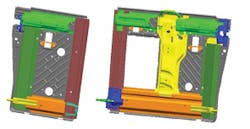

Faurecia Automotive Structures (FAS) is part of global Tier 1 supplier Faurecia, which manufactures seat structures, vehicle interiors, exhaust systems, and front-end structures for the world’s key OEMs. In terms of seat structures, a distinction is made between the front seat structures (FSS), as shown in FIGURE 1, and rear seat structures (RSS), which can either be individual seats or, for most medium-class vehicles, a seat bench structure, as shown in FIGURE 2. The RSS can be a single part or divided in segments (60-40 or 40-20-40). Regardless of their make-up, RSS have a very different design compared to FSS, which is determined by the vehicle’s dynamic performance requirements. In general, RSS comprise thin-sheet panels welded onto a strong substructure, whereas FSS comprise a backrest frame attached to a cushion structure by the recliner, and mounted on tracks attached to the car body for forward-backward movement.

Historically, FAS has been involved with laser materials processing since 1999 with the very first welding of recliner parts using CO2 lasers. In the following years, the number of applications grew steadil, until FAS first used CO and lamp-pumped Nd:YAG lasers for FSS backrest structures and tracks. Between 2003 and 2006, a revolution took place in the laser world with the advent of both fiber and disc lasers. In 2008, FAS reviewed its position and adopted a completely different mindset in its joining technology. Where in the past, metal arc gas (MAG) and resistance spot welding (RSW) were conventionally used for seat structures, remote laser welding was being pushed to the foreground as the preferred solution to weld different modules of a seat structure, offering flexibility in producing the required product performance, using a variety of material grades and thickness at a high productivity rate, and thus minimum cost.

With this mindset change also came a big step in terms of laser materials processing, with remote laser processing replacing fixed optic welding due to the process’ flexibility and productivity advantages. Now, a standard remote laser processing system at FAS is comprised of a 6kW Trumpf TruDisk laser, a 200 µm processing fiber, and a 450 mm focal length PFOscanning optic. (PFO stands for Programmable Focusing Optic, which is the Trumpf trade name for its remote processing scanning optics.) The PFO is mounted on a six-axis articulated robot arm from ABB used in two processing areas arranged in an L-shape configuration, as shown in FIGURE 3. The changeover to remote laser processing and the chosen cell configuration insures maximum equipment usage and improved quality at a lower cost, while offering a flexible production line capable of meeting the customers’ needs.

For a RSS, the use of remote laser welding is obvious: a large number of short (stitch) welds all positioned in the same plane is shown in FIGURE 4. The welds are made in an overlap configuration, joining a thin-sheet back panel, typically between 0.6–0.8 mm in thickness, to a subassembly that comprises mostly thin (typically between 0.8–1.5 mm in thickness) pressed sheet parts. The substructure is designed to give the RSS its required mechanical performance, e.g., stiffness and luggage impact. As all the welds are in the same plane, a 2D remote processing optic can be used. The main challenge for this application is in the design of the clamping arrangement, which must provide a minimum joint gap between the overlapping sheets to guarantee a consistent weld quality, and sufficient access for the laser beam so that the entire RSS can be welded with a minimum number of positions of the scanning optic.

FIGURE 3. Remote laser welding of FSS.

Today, steel is still the preferred material of choice for seat structures — this means from a processing point of view, no shielding gas is needed locally to prevent the weld region from oxidation. However, the use of a high beam quality solid-state laser results in amounts of plume and/or plasma just above the processing point, which creates a thermally affected region extending far above the processing point. As this impedes the efficient transfer of energy into the material, FAS is carrying out extensive studies to create the optimum processing conditions using air suppression mechanisms tailored to its specific seat structures and their clamping arrangement, and thereby to guarantee productivity and a consistent weld quality.

When using remote scanning optics for automotive seat structures, it is important to fully understand the capabilities of the scanning optic, from its positional repeatability to the beam characteristics over the full three-dimensional working range. The latter is especially important to assure a given weld aspect ratio and weld quality over a complete seat structure. In high-volume automotive seat production, with 1000 frames produced per day, the impact of fume build-up inside the laser processing cell needs attention. This is not something laser system suppliers or system integrators have a great deal of experience with, so in-house investigations are essential to assure, for a given product and clamping arrangement, an adequate cell extraction in combination with the aforementioned air suppression mechanisms.

Faurecia takes prides in delivering quality products to its clients. From a laser welding point of view, this means mastering the process to assure a consistently high laser weld quality. This has led to in-house standardization, not only of the cell configuration and operation, but on many other levels, including:

Process knowledge: In addition to the training offered by suppliers, Faurecia has developed its own training course to transfer knowledge on laser materials processing from the central advanced manufacturing engineering teams to the application teams and the plants where laser systems are or will be used.

Laser system acceptance: As each scanning optic is unique, Faurecia has developed its own procedure to characterize it and compare it against a Faurecia norm, to assure that the right quality is achieved for every weld in a complete seat structure.

Welding procedure: For each material grade and thickness combination used in its seat structures, Faurecia has developed weldability trials on coupon, substructure, and structure levels to guarantee the product’s required performance.

Welding acceptance criteria: Faurecia has developed welding acceptance criteria for frames, tracks, and recliners, defining the level of weld imperfections that can be tolerated for the individual products.

Process assessment procedure: This in-house procedure guides new program applications and plants through the necessary steps that are needed to implement laser welding technology onto the shop floor.

Since 2008, Faurecia’s vision in terms of remote laser welding of seat structures has become a reality. The possibilities offered by this process are truly impressive. Nevertheless, further development work is ongoing within Faurecia’s seating division to advance this technology to the limits. For example, with the remote processing optics, any weld shape can easily be produced, facilitating fitness-for-purpose welding by tailoring the shape of the weld to the required local mechanical performance. And, for the larger rear seat structures, the use of welding-on-the-fly with remote processing optics can further drive down the cycle time. However, this process, as with any other technology, is not one-size-fits-all, and the advantages and capabilities of remote optics need to be weighed against the restrictions of product design, which calls for a close collaboration between design engineers and process engineers.

And there remains work to be done by the suppliers, too. For instance, there is still variability in the beam characteristics over the optic’s full operating envelope. Although considered minimal from an optical point of view, these can affect the weld geometry and quality within the working range. And, to assist in the quality assurance for high-volume seat production, there is a strong need for more and robust solutions in terms of process monitoring. ✺

Dr. Ing. Geert Verhaeghe([email protected]) is master welding expert at Faurecia, based in Faurecia Autositze GmbH, Stadthagen, Germany.

About Faurecia

Faurecia (www.faurecia.com), an automotive supplier with locations in 33 countries, works in partnership with the world’s largest automakers. In 2011, the Group posted sales of €16.2 billion and is listed on the NYSE Euronext Paris stock exchange. Faurecia holds a leading position in each of its core businesses: automotive seating, emissions control technologies, interior systems (instrument panels, door panels and modules, acoustic solutions, etc.), and automotive exteriors.

With 84,000 employees, 40 research & development centers and 270 production plants, Faurecia supports automakers around the world, helping develop a safer, more comfortable, and more environmentally friendly car of tomorrow.

More Industrial Laser Solutions Current Issue Articles

More Industrial Laser Solutions Archives Issue Articles