An innovation in laser welding technology makes it possible to join two optically clear plastic parts for the first time. Previously, laser welding required one clear or “transmissive” plastic part and one dark or “absorptive” plastic part so the laser energy could pass through the clear plastic and be absorbed by the dark part. The new process, called “clear-on-clear,” is particularly timely, as patient-point-of-care, in vitro diagnostic test kits, which require optically clear test cartridges, are being used for rapid detection of COVID-19 antigens and antibodies. The new technology also opens up new design possibilities by allowing the use of a wide range of polymers for medical devices, drug delivery systems, and other in vitro testing products.

The new process combines Emerson’s Branson technology known as Simultaneous Through-Transmission Infrared (STTIr) laser welding with an ultrasonic deposition technology from Sono-Tek. The deposition process “pre-treats” one of the clear mating parts with a biocompatible laser absorber comprised of pigment dyes or carbon black microparticles suspended in a carrier fluid like isopropyl alcohol or acetone.

The laser absorber can be delivered to the surface of one of the clear mating parts through a variety of methods. It can be master-batched in the resin prior to molding, applied using a pad printing process or, for the greatest precision, spray-deposited on one of the plastic parts using Sono-Tek’s ultrasonic spray-deposition equipment. In the latter case, the laser-absorbing dye gets deposited on the surface of one of the parts using a spray pattern as small as 0.5 mm in width. The pigment’s fluid carrier immediately flashes off, leaving only the laser-absorbing particles—1 µm or smaller in size—on the surface.

During welding, the particles absorb laser energy and release heat that conducts through the weld zone of the two parts and bonds them together under a precisely controlled clamp force.

The ultrasonic spray-deposition system is described as being “designed to deposit minute quantities of pigment dye, measured in microliters, with coating thicknesses that are evaluated in the hundreds of nanometers on the surface of the coated parts.”

The new spray-deposition process was derived from an earlier Sono-Tek technology used to deposit ultra-thin, ultra-precise coatings on medical stents. The laser-absorbing properties of the new biocompatible solvent and pigment dye combination were derived from Sono-Tek’s light-absorbing coatings used on photovoltaic cells. This new technology involved an iterative process that transitioned the coating/deposition/weld process from absorptive-to-transmissive materials, culminating in the final transmissive-to-fully-transparent materials.

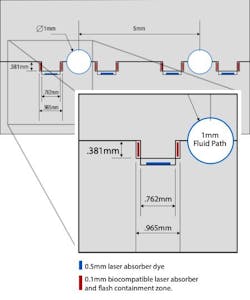

Depositing the laser-absorbing dye to the right location on an injection molded part is a challenge that requires extreme precision. Typical targets for such depositions include the interior surface of tongue-and-groove joints, or the interior surface of a “double-V” joint on one of the mating parts (FIGURE 1). By depositing the absorber into such enclosed joints, this new technology is able to both focus the laser-generated heat needed for the proper melt and create a “flash trap” that isolates the treated area of the melt from any sensitive microfluidic flow paths that may be located near the welded part.

The microfluidic parts used in today’s medical devices must be reliably bonded while maintaining precise, consistent dimensions along minute flow paths (FIGURE 2). To develop the technology required for such a precise bonding process. Sono-Tek perfected the method for applying the laser-absorber, and Branson perfected the spray-enabled laser welding process. As a result, the new clear-on-clear plastic laser-welding technology can reliably produce complex fluid paths while maintaining superior aspect ratios in the submillimeter flow path pitch.Combining with existing laser-weld processes

The biocompatible laser-absorber and ultrasonic spray deposition equipment can be “bolted on” to many existing Branson STTir laser welding applications, making it possible to manufacture clear-on-clear microfluidic parts economically and on an industrial scale for the first time. Weld cycle times can be measured in seconds, thanks to the high-speed welding capabilities of the STTir technology. The new spray-deposition process can also be adapted to produce multiple parts simultaneously, which allows the spray-deposition and laser-welding processes to be scaled up to accelerate production output even further.

Because the laser-absorbing pigment dye is so efficient at generating and conducting heat, it also helps overcome the challenge of large differences in the glass transition temperature (Tg) of different polymers being used in the joining process. Such capability significantly increases the range of thermoplastics that can be welded, regardless of their chemistry.

A typical application

A typical process involves using two clear-plastic, injection-molded parts, one of which will be placed in the Sono-Tek spray-deposition equipment where it will receive the laser-absorbing dye and serve as the absorptive half of the assembly. Next, the component parts are transferred to a laser welder (FIGURE 3), where laser energy is applied and a clear-on-clear laser-welded part is created.

This important new technology is invaluable for producing everything from serpentine flow paths, like the ones required for in vitro diagnostic systems, to IVD devices that demand optically clear flow paths. Thanks to this new clear-on-clear welding process (FIGURE 4), medical professionals can more simply and reliably observe automated blood cell counts in clear capillary-sized fluid paths, or perform critical patient-care procedures.