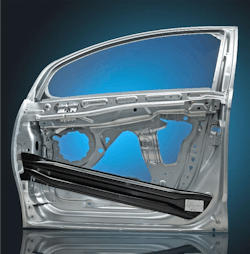

Metal and polymer joining is desirable in automotive lightweight constructions. With the advent of lightweight construction, the question of efficient joining processes of composites such as carbon or glass fiber-reinforced polymers (CFRPs or GFRPs) with metal parts has arisen (FIGURE 1). Joints of such different materials are of particular interest for safety and relevant for functional components in the automotive industry.

The requirements of the automotive industry are clear: joining processes must be fast, reliable, and automated. The TABLE gives a review of the three most common methods for joining composite materials with metal parts in an industrial process. Laser-based joining might be the newest in this list, and a number of questions have to be solved for the technology. It is not only about efficiency, but also about joint strength and aging of such joints. This article will present detailed research on these questions.Basics of laser-based joining technology

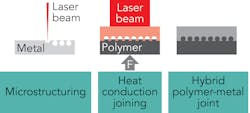

Laser-based joining of composites with metal parts is always a two-step process. At first, the metal part is treated with the laser to generate a microstructure on the surface. This can be done by a continuous-wave single-mode fiber laser with a nominal power of about 1 kW. The laser scans over the surface, creating regular grooves with undercut geometry (FIGURE 2).There is an alternative structuring process that should be mentioned. It can be done by an ultrashort-pulse (USP) laser with special pulses, allowing the formation of a sponge-like surface with cone-like protrusions. This self-organizing process has been observed on various materials such as steel, aluminum, silicon, and titanium. The grip of polymers on such a surface is even better than on the fiber laser-machined microstructures. The only problem is the slow speed of USP lasers. Once the USP lasers reach kilowatt average powers (as intended in another Fraunhofer project1), they might be the better choice for preparing a metal surface for composite joining.

In the second step of joining a composite material with a metal piece, the polymer is heated until it melts. Then, it is pressed into the microstructure and after cooling, it is well connected with the metal. Still, there are different ways to heat the polymer: One way is to heat the polymer (as in conventional injection molding) and press the mold into the grooves, while the other way is heating the metal part and pressing it against the cold polymer. Heat conduction makes the polymer melt, and then it flows into the microstructure. In both cases, the result is a hybrid polymer-metal joint.

The first step, the laser structuring, is fast and contact-free. The actual joining process can be well inserted in existing production processes like injection molding or pressing. So, laser-based joining as a whole is a fast and economic process that is well suited for mass production.

Mechanical stress tests

Within practical applications, hybrid parts may be subject to multiaxial, in-phase, or phase-shifted loads. For all applications, several questions arise: How much stress can such a joint endure? Where will it break? What does that mean for the joining process?

Experts at the Fraunhofer Institute of Laser Technology (Fraunhofer ILT; Aachen, Germany) have conducted a series of stress tests to answer this with various materials (FIGURE 4). In one case,2 they produced a test specimen consisting of a 1.5 mm stainless steel sheet metal and a 3-mm-thick stripe of glass fiber-reinforced polypropylene (PP) for tensile shear tests and an unreinforced PP for tensile tests.The metal surface has been processed by a 1 kW single-mode fiber laser with a focus diameter of about 40 µm. The laser created a reproducible undercut groove structure on metal surfaces. The polymer parts were heated with a 3 kW diode laser (at about 300 to 700 W) using a spot size of 7.5 × 25 mm². A clamping pressure of 3 bars was applied to attach both parts. The resulting joining area was 150 mm² for the tensile shear specimen (steel + GFRP) and 100 mm² for the tensile test (steel + PP).

Five samples of each type were destructively tested. The joint strength was measured for tensile shear load to 13.1 MPa for a groove pattern with 400 µm groove distance and 15.5 MPa for a groove pattern with 300 µm distance. For the tensile load, the samples withstand loads of 5.1 MPa (400 µm groove distance) and 9.1 MPa (300 µm groove distance).

Obviously, the denser pattern had a better grip, but it should be noted that a denser pattern increases the processing time. Similar tests were conducted with magnesium sheets.3 All tests showed that the laser-based joining technology creates a strong and reliable connection between metal and polymer parts.

Aging tests

Another relevant question for automotive serial production is: Do such connections fulfill the requirements for climate changes and corrosion? To answer this question, several tests were conducted. Essentially, they applied standard climate change cycles and corrosion test procedures to a set of hybrid joint test specimens.

For the tests, lap shear samples with different metals (steel and aluminum) together with different polymers (PP with glass fiber PP/GF30 and PP with talc filling PP/T40) were joined together using the laser-based joining approach. The climate change tests were performed according to VW PV 1200 with climate changes between 80° and -40°C.

The test cycles (12 hours) were repeated 2, 10, and 30 times. Before and after the climate changing tests, samples were tested in a destructive tensile shear strength measurement. All tests showed values between about 8 and 15 MPa. The interesting story was observed outside the joining area: after 30 test cycles, all samples with PP with talc filling failed in the plastic outside the joining area. In other words, the joints were stronger than the original PP material.

A similar behavior became apparent in the corrosion tests. There, tests were conducted according to VDA 621-415 for 7 days. This test included salt spraying and high-humidity conditions. Before the test, all samples endured between about 8 and 15 MPa. After the corrosion procedure, all PP/T40 plastics broke outside the joining area. The GFRP material broke inside the joining area, but at a higher strength than before the corrosion procedure.

The steel samples showed rust, particularly in the microstructured area. Some corrosion infiltration into the joining zone was apparent, but this had no measurable influence on the joint strength. The aluminum sheets showed also signs of corrosion on microstructured areas outside the joining zone, but not inside the joining zone. An immediate conclusion was to avoid any open microstructured areas.

The laser-based joining process has been tested to create highly reliable connections between sheet metal and plastics. Standard climate and corrosion tests did not show an influence on the joining strength. After some aging, the open plastic rather than the joining area breaks. Open microstructured areas on the metal should be avoided.

REFERENCES

1. D. Hoffman, J. Limpert, and A. Thoss, “Ultrashort-pulsed laser sources with kilowatt power for industrial applications,” Laser Focus World, 56, 1, 65–68 (Jan. 2020); https://bit.ly/ThoRef1.

2. K. van der Straeten, C. Engelmann, A. Olowinsky, and A. Dillner, “Comparison of laser-based joining approaches for plastic-metal-hybrids–strength vs. process speed,” Proc. Hybrid Mater. Struct., 203 (2018); https://bit.ly/ThoRef2.

3. C. Engelmann, C. Hopmann, and S. Wurzbacher, “Laser beam microstructuring of magnesium sheets made of ME20 – Potentials for the in-mould assembly of plastic/magnsesium hybride joints,” Joining Plastics, 13, 3–4, 182–189 (2019).