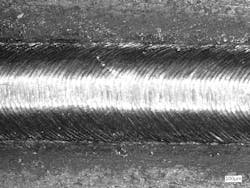

The Super Pulse Technology (SPT) controller for pulsed laser systems from Sigma Laser (Oberursel, Germany) ensures optimal control of heat input during laser cladding, thereby increasing the quality of the weld seam and preventing cracking. SPT uses the modulation of laser pulses to precisely control the heat input into the material, which allows the welding process to be optimally adapted to the solidification characteristics of the materials used. As a result, the user has a grip on the nucleation rate when solidifying the metallic melt and can produce welds with a very fine-grained, homogeneous microstructure.

The controller modulates the laser pulses in the short-term range and reduces interruption times down to under 50 μs. It allows the regulation of pulse durations in the millisecond and time constants in the microsecond range, as well as a modulation of the frequencies up to 3000 Hz. Between the start and stabilization pulses, a longer, temporal interruption of a few milliseconds, for example, can also be set for an intermediate cooling and thus limited temperature increase of the melt volume and the heat-affected zone in the base material.

First applications in the field of medical technology and aerospace show that build-up welding with modulated laser pulses achieves the desired results in these fields.

For more information, please visit sigma-laser.com.