The Thin Film Processing group at the Fraunhofer Institute for Laser Technology (Fraunhofer ILT; Aachen, Germany) specializes in the post-treatment of coatings using lasers, with particular focus on the aerospace industry.

One laser processing method the group offers islaser treatment of printed, thin electronic layers. Wet coating processes such as inkjet, pad, or dispensing printing and many others are used to deposit the necessary materials onto the components to integrate electrical functions into them. Depending on the process, different layers can be applied that vary in thickness, width, or structure.

However, all layers require heat post-treatment, using furnaces that take a long time and are very energy-intensive because the entire component is heated. With the group's laser treatment method, a laser beam works precisely and quickly, processing small structures on components in a short time with the coating heated locally to temperatures above the damage threshold of the component, but without damaging the component itself. First, the laser beam dries the layer to remove solvents, leaving only the functional particles--so, for example, only silver, gold, etc. remain. The laser then partially or completely melts these micro- or nanoparticles and connects them so that they can, for instance, conduct electricity.

Fraunhofer ILT is also demonstrating an additively manufacturedstrain gauge used to measure the elongation of a component. Researchers have developed a method for directly applying the sensor to substitute the conventional foil strain gauge, which commonly has to be applied manually to the component. To achieve this, the scientists deposit an insulation layer on a metallic component, onto which a measuring grid including conductor paths is printed by means of inkjet or aerosol jet. All post-treatment is done using laser radiation. If necessary, a final encapsulation with a further insulation layer follows.

A strain gauge sensor that can be applied directly and automatically to the component combines printing and laser technologies. (Copyright: Fraunhofer ILT, Aachen, Germany)

Fraunhofer institutes are working on the application of electronic functional layers on components from the automotive, aviation, and lighting sectors. With the new technology, it will be possible to individualize mass components, such as doors, using digital print and laser processes. In the future, electrical signal and power interconnects for different car configurations may be applied directly and automatically to the components. In addition to printing electrical conductors, this technology enables the integration of new sensors and lighting with surface structuring using laser ablation: Cavities of almost any shape can be manufactured, which will then be coated with an electrical insulation layer using digital printing technologies. Laser post-treatment of the insulation layer is followed by printing another layer of electrical conductors or sensors and their laser-based post-treatment.

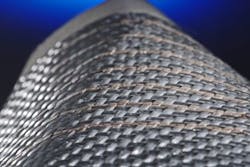

Carbon or glass fiber fabrics are in demand for the aerospace industry due to the need for weight reduction. Using a combination of printing and laser technology, the researchers can apply electrical functional layers directly to the fabrics, which then are embedded into the component matrix material. The functional elements are thus protected in the fiber composite component. In addition to electrical interconnects for new sensors and lighting elements, heating structures in aircraft wings, for example, could also be manufactured in this way.

Electrical functional layers can be applied directly to a glass fiber fabric that will be used to manufacture fiber composite components using a combination of printing and laser technology; sensors or heating elements could therefore be integrated into aircraft wings. (Copyright: Fraunhofer ILT, Aachen, Germany)

Fraunhofer ILT also demonstrates how plug contacts can be gold-plated more selectively: The gold is only applied at spots where the electrically conductive contact is actually required, reducing the amount of gold needed when compared to a fully gold-plated part, but with design flexibility and independence from long delivery times that plague the industry.

Battery manufacturersmight be interested in a laser-based method for drying battery electrode layers that are prior deposited as pastes to copper foils. This method saves both energy and installation space.

Fraunhofer ILT also uses laser radiation to create functional layers for microelectronic accelerometers. A piezoelectric actuator, however, is used to generate motion, as it deforms when voltage is applied. Here, the researchers are investigating how the piezoelectric layers can be applied in a more cost-saving way using laser radiation for crystallization. Fraunhofer ILT will be presenting these developments at the Hanover Fair 2019.

For more information, please visit ilt.fraunhofer.de.