A device combining a laser and diamond cutting system has been developed at Western Michigan U., for use in processing hard, brittle materials that are difficult to machine.

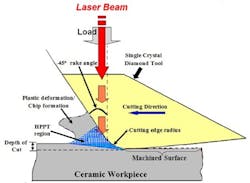

The technology, developed by John Patten and Deepak Ravindra, combines a fiber laser (typically near-IR) with an optically transparent diamond cutting tool. Essentially, the laser source's high temperature (1,000 °C-plus) and pressure (> 100 GPa at the cutting point) thermally heats and softens the material's surface to make it more ductile and easier to machine with the high-stress diamond tool.

Existing manufacturing processes using diamond tools to cut hard, brittle materials create cracks that must be subsequently polished out, not to mention significant tool wear, both of which cost time and money. This technique softens the material before processing so no cracks or fractures are ever introduced, eliminating those costs and time, explains Ravindra.

Materials being explored include ceramics and semiconductors, with early target applications identified in microelectronics (microelectromechanical systems/MEMS), electronics, and optics. Other hard, brittle materials being explored include porcelain and stone.

A spinoff company, Micro-Laser Assisted Machining Technologies (μ-LAM), has been formed to commercialize the technology. Their work has been backed by more than $2.3 million in funding since 1999, mostly from the National Science Foundation (NSF). A description of their work will be presented at next month's North American Manufacturing Research Conference (NAMRC) at Notre Dame in South Bend, IL (paper 7777). They received a SMA Innovation award in 2009.

Schematic illustrating the concept of the μ-LAM process. (Source: μ-LAM)

Sponsored Recommendations

Sponsored Recommendations

Request a free Micro 3D Printed sample part

April 11, 2024

How to Tune Servo Systems: The Basics

April 10, 2024

Voice your opinion!

Voice your opinion!