Vivian Merchant

Laser cladding appears to require a dedication to the specialty to make it successful

Laser cladding is one of several ways in which a wear- or corrosion-resistant surface layer can be applied to repair or extend the life of components. Because industrial lasers are a controllable heat source, the laser cladding process is characterized by good control of the heat input to the workpiece. This results in low dilution of the coating layer (mixing of the coating with the substrate) and low distortion of the workpiece. Other methods, such as submerged arc welding or shielded gas metal arc welding, require significantly higher heat input to the part, greater dilution, the potential of greater distortion of the part, and a rougher surface that requires grinding if a smooth surface is required. Non-welding methods, flame spraying and plasma spraying, produce coatings that are mechanically rather than metallurgically bonded to the surface. Generally speaking, coatings produced by these methods are thinner than coatings produced by laser or arc welding processes.

By the early 1980s, laser cladding was identified as a process with a significant edge over the various competing processes for depositing wear- and corrosion-resistant coatings. The three main suppliers of high-power industrial lasers (Spectra Physics Industrial Lasers, Avco Everett Metalworking Lasers and the United Technologies Research Center, later United Technologies Industrial Lasers), none of whom currently exist, had developed an in-house expertise at laser cladding and were willing to address the needs of customers. A patent, #3,952,180 issued to Avco, said to be the dominant patent in this technology, was made available to all, on a non-royalty basis, to advance the technology. Still, the applications by-and-large did not become popular. Lists of locations where laser cladding was being used in the mid-1980s are not very different from current lists prepared today. Of the more than 150,000 industrial laser systems sold since lasers were invented, less than 100 are performing laser cladding operations.

Why has laser cladding seen so little market penetration? Here we consider only laser cladding for surface modification and not the extension of this process (called direct metal deposition or laser engineered net shaping (LENS) by different manufacturers) to building up solid objects by laser powder consolidation. This article is also limited to the installed base of lasers in North America, which are most familiar to the author; however, it is believed that laser surface modification practices in general have seen much wider applications on other continents.

Laser cladding is a production application in cladding of steam turbine blades, for manufacture of gas turbine blades on both sides of the Atlantic, for repair of gas turbine blades, for hard facing of oil field valves, hard-banding of drill rods, and surfacing of automotive and diesel valves. Water walls for power plants, paper mill components, and components of earth-moving equipment are being laser clad. Military components currently being laser clad include catapult launchers and drive shafts.

In the automotive industry, the valves of a non-commercial vehicle will be subject to 300 to 500 million thermal and mechanical cycles in an automobile's lifetime, and an exhaust valve in particular is subject to a stream of hot gas that may contain soot particles and corrosive constituents. In the early days of laser technology, numerous research facilities showed pictures of laser-clad valves in their publications and literature. How many of these laser systems for cladding automotive valves were put into production? To the best of this author's knowledge, only two, and these are not in North America. The chief reason for this lack of market penetration is the availability of somewhat less expensive equipment for coating valves using plasma transferred arc (PTA) welding, which produces deposits with the low levels of dilution. Deposits produced by laser welding do not have a demonstrated advantage over those produced by PTA, so it is difficult for manufacturers to justify the extra expense.

This is an example in which high technology has been applied to a process typically considered low technology. Because lasers are relatively expensive, it is easy to justify using robotic control and computer-controlled manipulators to make the best use of the controllable heat source. Manufacturers are reluctant to apply the same degree of controlled manipulation to inexpensive heat sources. But a highly controlled motion system applied to the plasma arc welding process has allowed repeated, high-quality deposits to be put onto valves, so little advantage is seen to using the laser process.

Numerous suppliers and repair shops in the airborne gas turbine industry around the world use lasers for reinforcement of the shroud interlocks and repair of blade tips. Competing processes for these applications include gas tungsten arc welding (GTAW) for the shroud interlocks and both GTAW and plasma arc welding for the blade tips. Many manufacturers and blade repair installations have laser equipment installed. Reasons why the laser process is finding increasing success in these applications include the fine control of the heat input in the laser process, which leads to accurate powder deposition at locations where it is needed.

In this successful application there is still considerable room for market growth, even though it is perceived as one of the more sophisticated of the industrial laser applications, requiring special skills. There is a limited number of people in North America who have developed these skills, and a limited number of equipment suppliers. One vendor of laser cladding equipment has sold a system into a shop where it was the first piece of equipment with computer-controlled (CNC) manipulators.

The laser cladding process equipment is usually applied to high-value products, consequently potential users require samples to be produced before they will commit a considerable amount of money to equipment purchase. But demand for the equipment is low, and equipment vendors cannot afford to have a laser cladding machine in their application laboratories or showrooms for occasional sales. The vendor must also have machine tool operators skilled in the laser cladding process as well as tooling to process a variety of part shapes in order to produce parts for potential customers. Some suppliers have provided one or two machines each, while only a few major vendors that specialize in this area have provided the largest amount of cladding equipment currently in use.

Successful laser cladding requires an accurate and controllable method of applying filler metal at the leading edge of the weld pool created by the laser beam. Use of an uncontrolled or poor method of adding filler metals results in poor utilization of the often expensive filler metal. This lack of control can be tolerated in high-heat-input arc welding processes or cladding with a multi-kilowatt laser because the filler metal inevitably gets absorbed into the larger weld pool. Laser cladding for repair of detail in components such as turbine blades requires more control in the powder deposition, which has lead to the development of highly controlled methods of adding the filler metal.

Sandia National Laboratories has developed a computer-controlled wire feeder that allows controlled deposition of wire into a weld pool; this design of wire feeder has been commercialized by Alabama Laser Systems (Munford, GA). Several suppliers of powders have developed powder feeders with a higher degree of control than possible with powder feeders used for other applications.

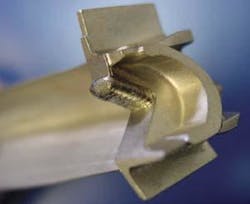

Several different styles of nozzles have been developed for applying the beam and the powder together at the workpiece. Accurate deposition of the powder inevitably means the powder nozzles must be close to the weld pool and, hence, must be water cooled. Nozzles have been developed at Imperial College in the United Kingdom, Sulzer Innotec in Switzerland, Fiat Automotive in Turin, IREPA laser in France, the Laser Institute in Canada, Battelle Columbus Laboratories, Huffman Corporation, and General Electric Aircraft Engines in the US. The proprietary nature of these designs and lack of information available to small users has been another factor in slowing the acceptance of the laser cladding process. Many users of the laser cladding process have developed their own nozzle design, but there is little technical information available to assist in this process.

Not all powders of nominally identical composition are suitable for the laser cladding process. Some powders prepared by gas atomization contain a fine porosity. Because the laser process is a low-heat-input, high-cooling-rate welding process, there is insufficient time available for the porosity to escape from the weld pool. A ground surface prepared with such a powder is found to contain fine porosity, which may frustrate attempts to introduce the laser cladding process. This is avoided by careful evaluation of powder suppliers.

A final reason for the slow acceptance of the laser cladding process is the perception that laser cladding is a process requiring more sophistication than other laser applications. Laser cladding has been economically profitable for companies in which there has been a champion who will sponsor the adoption of the technologies. Other more established processes such as laser cutting don't need a champion because the economics of these technologies will speak for themselves, and companies generally have the necessary expertise in-house to adopt the new process. Laser cladding requires the company to have three sets of skills, the CNC skills, the welding skills and the laser skills. The laser skills can be provided by the equipment vendor in a short course, as in the case of cladding, but the other skills must be provided in-house or by hiring outside technical people.

Laser cladding knowledge has been developed by a relatively scarce supply of "champions." For example, personnel from Westinghouse R&D assisted in the founding of a job shop, which is now a successful Praxair operation. A graduate from Imperial College established the laser cladding technology at Quantum Laser Systems, which is now a part of the Honeywell-Allied Signal organization. Personnel from IREPA laser in France established the Gremada Industries laser operation. By contrast, a number of smaller shops have attempted to add laser cladding to their operations. But unless they have a full-time champion to provide the expertise and bring in a lot of business, the attempts to provide all services for all customers appear to be less successful than that seen in the shops such as Gremada and Praxair that specialize in the laser cladding operation. In general, laser cladding appears to require a dedication to the specialty to make it successful, and companies, either processing shops or equipment vendors, that attempt to add laser cladding to their diverse capabilities do it much less successfully than companies that specialize in it.

Vivian Merchant currently works as a consultant. He can be contacted at [email protected].