New diode-pumped system brings laser peening to the factory floor

JEFF DULANEY

Material enhancement has long been at the leading edge of technological innovation. Powerful machines require robust components, but material limitations present a critical obstacle to performance optimization. Laser shock peening (LSP) resides at the forefront of material enhancement, employing high-energy lasers to generate deep compressive residual surface stresses for proven metal fatigue resistance.

Laser peening has been implemented by original equipment manufacturers (OEMs) in the aviation and power generation industries to enhance their products' resistance to cracking caused by fretting, corrosion, foreign object damage, and fatigue. Now, after nearly 50 years of technological advancement, the first line of turnkey industrial laser peening systems is integrating the technology into manufacturing facilities around the world.

Origins

Laser peening as a metal improvement process was born in the 1970s out of research at the Battelle Memorial Institute (Battelle; Columbus, OH). Researchers at Battelle, led by Dr. Jeff Dulaney, were exploring whether high-energy, short-pulse lasers could be used to improve material properties. They initially demonstrated significant tensile strength improvements in 7075 aluminum alloy specimens after processing them with a 1.2–2.2GW/cm2, 32ns Gaussian pulse. The Battelle laser delivered energy outputs up to 500J, but the system's size (over 15m long) and slow pulse rate (one pulse every 6–8 min.) made it impractical for industrial material processing.

In the 1980s, Battelle engineers and scientists designed and built an advanced prototype system for laser peening. The high-powered system incorporated long-pulse flashlamps with a high-repetition-rate oscillator, transforming the previously hulking, single-pulse laser into a 200kW burst laser operating at 1Hz.

In the early 1990s, the US Air Force encountered foreign object damage (FOD) issues with General Electric (GE) F101 engines in the B-1 Lancer. GE needed an innovative material enhancement solution to mitigate FOD, and they partnered with Battelle to explore the benefits of laser peening F101 fan blades.

After processing samples and subjecting them to fatigue testing, Battelle scientists demonstrated that laser-peened blades with simulated FOD damage retained fatigue lifetimes superior to those of new, undamaged blades. This was a landmark result, as the Air Force had previously dedicated extensive resources to laborious manual inspections of all F101 first stage fan blades before each flight.

With potential cost savings in the tens of millions over the life of the B-1, the Air Force authorized the production development of laser peening for fatigue enhancement, and GE Aircraft Engines began laser peening all F101 first-stage fan blades using a newer-generation, two-beam, 50J laser system modeled after the single-beam, 1Hz Battelle design.

Commercialization

Inspired by the results of the F101 study and subsequent Air Force demand, Dr. Dulaney left Battelle and founded LSP Technologies (LSPT; Dublin, OH), with the sole purpose of commercializing laser shock peening. The company acquired an exclusive worldwide license to Battelle's laser peening patents, and began marketing laser peening equipment and services as a fatigue enhancement solution. LSPT constructed GE Aviation's initial laser peening systems, as well as their own in-house production system for commercial laser peening: a 20W, neodymium (Nd) glass, flashlamp-pumped system paired with a production work cell and 400-lb.-capable part-handling robot.

LSPT engineers now faced the challenge of maturing LSP technology to its maximum effectiveness and throughput. Higher repetition rates required more robust optical glass to withstand cyclic heating from the flashlamps, so LSPT partnered with specialty glass manufacturer Schott AG to identify stronger laser glass rods with tailored Nd doping concentrations for laser peening. Deeper residual stress profiles required more sophisticated modeling tools and process controls, while complex surface geometries necessitated integrated robotics for precise part manipulation. Throughout the technological maturation of laser peening, LSPT developed and patented numerous advancements, including innovative methods for beam delivery, laser pulse slicing, overlay application, and quality control.

These technological improvements made laser peening more efficient and less expensive, leading to new commercial applications and greater market demand. LSPT began performing production laser peening services for customers in the aviation, transportation, power generation, and tooling industries—all of whom are benefiting from significant increases in the fatigue strength of their laser-peened components. Laser peening was proven to consistently extend the service life of metal components by improving their resistance to fatigue, cracking, and damage effects, while reducing maintenance and inspection requirements for critical parts.

How laser peening works

Just as the name implies, laser peening uses high-energy laser pulses to peen metal surfaces for improved material characteristics. Peening is a cold-working, mechanical process that imparts beneficial stresses into material through compressive surface hardening. While traditional peening methods rely on the brute kinetic force of hammer blows or projectile shots, laser peening employs high-energy laser pulses to produce confined plasma bursts that direct compressive stress waves into target material. As a mechanical cold-work process, laser peening is distinct from other laser-material processes that rely on thermal energy to induce heating or melting.

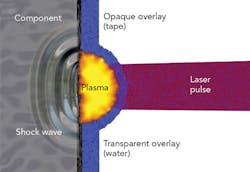

Laser peening is performed using a high-energy, short-pulsed laser system and an assortment of process overlays. An opaque overlay (typically vinyl tape or paint) is applied to the target surface prior to processing to absorb the laser energy and protect the part surface from thermal effects. A transparent overlay (typically water) is applied over the opaque overlay, and acts as a tamping medium to confine the rapidly expanding plasma and amplify the pressure pulse at the surface of the part.

When the laser pulse is directed to the target, the pulse passes through the transparent overlay and strikes the opaque overlay, generating a high-pressure, rapidly expanding plasma. The high pressure of the confined plasma burst drives a high-amplitude compressive stress wave deep into the target surface, inducing plastic deformation and compressive residual stresses within the part (FIGURE 1).

The key to enhancing metals like titanium or steel is to produce a stress wave with an amplitude greater than the material's dynamic yield strength. If the stress wave amplitude exceeds this value for a given metal, the material will undergo plastic strain as dislocations in the microstructure produce compressive residual stresses in the part.

Operational parameters

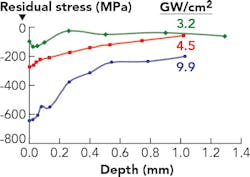

Laser peening tailors compressive residual stress fields by controlling the intensity and coverage of the laser pulses. Different metals require different laser peening power densities (GW/cm2), depending on the material's dynamic yield strength. For example, laser peening high-strength steel requires power densities in the range of 9–10GW/cm2. Power densities are a function of laser pulse energy, laser pulse width, and spot size, and will dictate the peak pressure of the shockwave on the surface of the part (FIGURE 2).

Laser peening is the only industrial material processing technology that utilizes high-energy laser pulses with sub-50ns pulse widths. Short pulse widths generate greater peak power, and produce higher compressive stresses at the part surface. Laser peening systems incorporate a Pockels cell pulse slicer to shorten the pulse rise time for short bursts of intense irradiance. This produces optimal power densities for driving compressive stresses deep into a workpiece.

Effective laser peening coverage is achieved by overlapping layers across the process area. Spots are typically applied in rows with at least a 33% overlap, producing a uniform field of compressive residual stresses that inhibit the propagation of surface or near-surface cracks.

The next generation

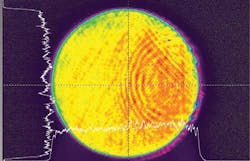

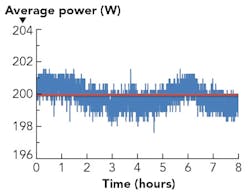

Now, this surface enhancement technology is available as a fully integrated turnkey system: LSP Technologies' Procudo 200 Laser Peening System is engineered specifically for manufacturing environments (FIGURE 3). Equipped with an embedded 200W diode-pumped Nd:YLF laser (FIGURE 4), the system can deliver 10J of energy per pulse at a repetition rate of 20Hz. The system features a flat-top beam (FIGURE 5) with selectable energy and pulse widths, while the diode-pumped oscillator provides a stable, repeatable output for high-repetition processing with narrow variability (FIGURE 6).

The system incorporates a modular design, engineered for integration directly into manufacturing lines. Selectable parameters provide operators the flexibility to laser-peen parts of any size or shape, while the custom control and diagnostics package affords real-time data analysis and process control.

The Procudo Laser Peening System has already attracted attention from materials scientists and engineers around the world, resulting in research-oriented laser peening installations on multiple continents. A system has been installed at Guangdong University of Technology (GDUT; Guangzhou, China), and another is scheduled for installation at the Center of Applied Aeronautical Research (ZAL; Hamburg, Germany) before the end of 2017. These installations represent the first opportunity for many researchers to study the benefits of laser peening on production-capable laser peening equipment.

The net consumer benefits for widespread laser peening adoption will be safer products, more reliable equipment, and enhanced engineering capabilities across a broad range of industries. The process enables longer service lifetimes, increased component capability, more robust engineering designs, and countless other cost-saving advantages. As engineers and manufacturers continue to push the limits of material capabilities, laser peening will remain an invaluable tool to ensure that components meet the demands of innovation.

ACKNOWLEDGEMENT

Procudo Laser Peening System is a registered trademark of LSP Technologies.

Dr. JEFF DULANEY([email protected]) is with LSP Technologies, Dublin, OH; www.lsptechnologies.com.