Engineers describe examples of femtosecond laser micromilling applications

In this article, Clark-MXR (Dexter, MI) laser micromachining engineers who say "where your imagination of the very small is realized" share femtosecond laser applications with Industrial Laser Solutions readers.

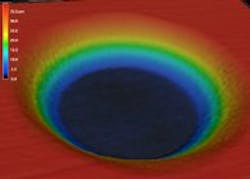

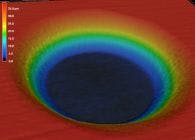

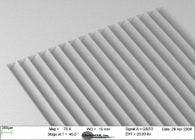

Femtosecond laser micromilling, or ablative laser processing, removes material in virtually any shape or pattern. Cut widths down to a few microns are achievable and submicron kerfs are possible for very thin materials. Femtosecond laser machining enables repeated manufacture of precision components with complex patterns. 3D blind features can be created with depth resolutions within a few percent of the feature depth, and resolutions as high as a few tens of nanometers can be performed on production parts.

Here are two examples of femtosecond laser micromilling applications:

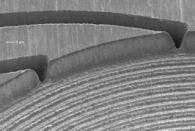

Serial sectioning. Applying ablative, or subtractive, patterning processes to an entire material surface exposes underlying areas that can be examined and characterized using a variety of microscopic or spectroscopic analytical techniques. Repeating the process allows for 3D reconstruction of a sample often called serial sectioning or 3D tomography.

Wear and defect simulation. Precision laser micromilling into pristine surfaces, with highly controlled dimensions, creates defect standards that can be used to calibrate test inspection equipment for critical components like ceramic ball bearings. Similarly, removing controlled amounts of materials from surfaces creates artificial wear for test parts in industries such as automotive and heavy equipment. The machined results can be processed on many materials, including ceramics, metals, composites, and exotic materials like diamond.

For more information, please visit www.cmxr.com.