The UKP Workshop, held April 10-11, 2019, in Aachen, Germany, welcomed more than 170 participants from 14 countries, who came together to discuss the latest trends in the development of ultrashort-pulse (USP) laser technology for industrial applications. Ron Schaeffer, Industrial Laser Solutions Editorial Advisor, covered this meeting for ILS.

"The USP laser has found its way into the industry. The next goal is to provide lasers with power, as is the case with CO2 and fiber lasers, which are currently used for material processing of macroscopic components. The challenge is how to get the photons to the workpiece," said Dr. Arnold Gillner, head of the Ablation and Joining competence area at the Fraunhofer Institute for Laser Technology (Fraunhofer ILT; also in Aachen), to participants.

Dr. Arnold Gillner explains to attendees that "the challenge is to get the photons to the workpiece." (Copyright: Fraunhofer ILT, Aachen, Germany)

There was a consensus on beam sources—lasers up to 100 W have now made it to the market and systems with several 100 W are available and already being integrated into the first machines. Soon to be added are USP lasers in the multikilowatt range, such as those developed by the Fraunhofer Institute for Applied Optics and Precision Mechanics (Fraunhofer IOF; Jena, Germany) and Fraunhofer ILT in the Advanced Photon Sources Fraunhofer Cluster of Excellence. Both institutes have set new world records in recent months: The Fraunhofer IOF group demonstrated 3.5 kW average output power from a fiber laser system, while the Fraunhofer ILT group showed 500 W at only 30 fs pulse duration from a Yb:Innoslab laser.

Altogether, 12 institutes are working in the Advanced Photon Sources cluster. Together, they want to make newly developed beam sources available along with corresponding system technology for a wide variety of applications in two application labs in Jena and Aachen.

Laser developer Eric Mottay (Amplitude Systèmes) emphasized that system technology for the new lasers can only be developed when the different technology carriers cooperate closely. This became apparent in the following lectures on fast scanners, multibeam systems, and special optics: Together, laser manufacturers, scanner experts, and users are working on a multibeam concept in which an energy-rich laser pulse is split into multiple individual laser beams and guided parallel over the surface to efficiently process larger areas.

In detail, Stephan Brüning of Schepers (Vreden, Germany) tested the multibeam concept for structuring printing rollers. Previously, four lasers were used in parallel—now, the 500 W average power of a USP laser is distributed over 16 partial beams by means of a diffractive optical element. By means of acousto-optic modulators, the partial beams can be controlled independently and achieve significantly higher productivity.

The design of optics with up to 196 similar partial beams was explained by Oskar Hofmann from RWTH Aachen University. The challenge of developing these optical concepts lies in the compensation and correction of the different aberrations.

Benedikt Nohn of Volkswagen (Wolfsburg, Germany) demonstrated how efficiency gains can also be achieved with individual beams. His example was the structuring of tools for embossing interior design elements. Optimized scanner technology more than doubled throughput.

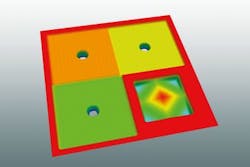

"The laser makes a continuous process chain for digital photonic production possible," which is the vision of Reinhart Poprawe, the outgoing director of Fraunhofer ILT. Markus Niessen from Fraunhofer ILT discussed the usual approaches and how to cut the computational time dramatically with a reduced model. Microscopic interaction processes and material effects are considered separately from macroscopic effects. In the long term, Niessen has a clear strategy: "Our goal is right-first-time production."

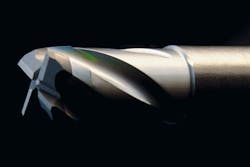

Carbide drills can be produced fully automatically from simple blanks; the machine receives blanks and geometry data, and the laser parameters are automatically selected. (Copyright: Dr. Claus Dold, EWAG AG, 2018)

The progress of the USP laser technology can now be read off the quality of the applications. In the workshop, Claus Dold of EWAG (Etziken, Switzerland), an expert in the manufacture of tools made of ultrahard materials, explained how well the USP laser can process polycrystalline diamonds or carbide materials. He presented a complete manufacturing system, where the operator only has to enter the geometrical data and insert blanks, for producing carbide drills. The laser machine itself selects the necessary settings and produces the drills with micrometer precision. The machines can be fully automated and operated in a global network. In a digital marketplace, production capacities can be controlled globally and adapted to demand.

Multiscale simulation for digitizing the USP structuring process of metallic foils is shown. (Copyright: Fraunhofer ILT, Aachen, Germany)

Now that laser sources in the multikilowatt range are becoming available, the main advantage of USP technology—extremely high precision in processing—will lead to its more-widespread use. Efficient process technology and a very good understanding of the process are prerequisites for industrial application. New applications from generation of extreme-ultraviolet radiation to quantum technology are on the rise. A new challenge must be the protection against x-rays.

For more information, please visit www.ultrakurzpulslaser.de.