In the medical device manufacturing industry, there is an increasing demand to drill, cut, skive, texture, and machine both plastic or metal/plastic combinations, from stents to catheters and wire stripping to balloon texturing. These types of applications and the level of quality and dimensional accuracy needed align well with the processing capability of ultrashort-pulse (USP) lasers.

Ultrashort-pulse lasers have been industrially reliable tools for many years. With recent increases in power and pulse energy, coupled with lower prices, these lasers are now economically viable for more manufacturing applications. There are a wide range of USP lasers commercially available, each with a specific set of attributes. We at Amada Miyachi America have our own application labs to test and select the best laser for the job, and this article shares some of our experiences specific to polymer processing.

The key laser parameters we have identified for polymer processing are pulse width, energy, and frequency, as well as wavelength.

Pulse width

Our pulse width testing covered a range from 300fs to 10ps, maintaining consistent pulse energy and frequency across this range. The same laser with adjustable pulse width was used, so all other beam parameters were as equivalent as possible. FIGURE 1 shows the results for fluorinated ethylene propylene (FEP) and polytetrafluoroethylene (PTFE) materials. From a simple removal rate perspective, the femtosecond pulse duration is the best choice and with orders-of-magnitude-greater peak power over the longer pulse widths, this perhaps is not a big surprise.

It is also worth noting that, specifically in relation to medical devices, the shorter femtosecond pulse width always provides superior feature quality, as it is a pure sublimation removal process. With no melting, there is no topside or bottom side burr, and more control over feature dimensions. The longer picosecond pulse widths, while still providing good quality, do show burring effects, indicating that some material melting is present.

Pulse energy and frequency

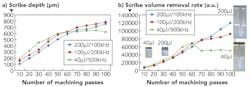

Three pulse energy levels were used at a constant average power of 20W and a pulse width of 290fs: 200µJ at 100 kHz, 100µJ at 200 kHz, and 40µJ at 500 kHz. The question is if it is better to use higher pulse energy at lower frequency or lower pulse energy at higher frequency.

FIGURE 2 shows that both the depth and volume removal for a multipass scribe line is better using the low energy and high repetition rate of 50µJ/500 kHz to around 0.5mm deep. Beyond this thickness, the narrow width of the scribe likely blocks the energy from reaching deeper and, therefore, self-terminates at this depth. In contrast, at the 0.5mm depth, the higher pulse energy of 200µJ starts to create a much wider scribe, which can be seen in the scribe profiles after 100 passes in FIGURE 2b. The wider width likely allows the laser energy to reach deeper into the bottom of the scribe line and continue to increase scribe depth at a linear rate with more passes. This would also provide reduced area removal feature cycle times for depths beyond 0.5mm, as the line spacing between the machining tool paths can be minimized.Aside from the processing data, we have observed that using a higher pulse energy increases the process depth of focus. This increase in the part-position tolerance along the focus axes is important, as the most common problem of a process falling out of specification is maintaining the position of focus relative to the part—the larger this tolerance is, the better for the process. Although this is application-specific, the range of pulse energy to maximize depth of focus while maintaining feature quality and removal rates appears to be between 40 and 100µJ.

Wavelength

When testing wavelengths, there are a couple of key points to appreciate—longer wavelengths offer higher average power and pulse energies, and lower wavelengths offer smaller spot sizes for the same optical setup. Therefore, it is almost impossible to have an absolute wavelength vs. wavelength test.

Our focus for this test was whether infrared (IR), green, or ultraviolet (UV), with all the associated parameters at those wavelengths, provide the best solution for removal rate, quality, and processing window. Therefore, the test was a best processing performance test between the three wavelengths to produce good-quality features in polyether block amide (Pebax), the results of which are shown in FIGURE 3. Here, it is clear that the removal rate vs. quality favors the green and UV wavelengths. When the higher pulse energy/average power of the IR wavelength is used, it tends to overheat the material as opposed to providing increased removal rate. There was not a big difference between green and UV from a removal rate standpoint, but the UV wavelength did show a better feature surface finish and less debris.

The original perception was that femtosecond pulses effectively normalize absorption across all materials irrespective of wavelength by effectively beating the material into submission with a literal avalanche of photons. This is not the case for polymers. An additional advantage of using green or UV wavelengths with respect to the processing window is to maximize the processing depth of focus, which has already been touched upon as a key benefit to maintaining a production process.

Summary

Ultrashort-pulse lasers are great tools for processing plastics for medical devices. Our testing demonstrates that from a processing perspective, a femtosecond laser is the correct tool for polymer processing. The removal rate tends to favor mid-range pulse energy from 40 to 100µJ and higher frequencies between 200 and 500kHz. Also, there is a clear advantage to using the shorter green and UV wavelengths for processing removal rate, surface finish, and maximizing the process window.

Of course, every application is different and there are always budgetary constraints that factor into the laser selection. As for any application, it is always best to ensure that sufficient testing is completed to make the best choice for the process and production requirements.

ACKNOWLEDGEMENT

Pebax is a registered trademark of Arkema.