SAMI LAROUI

Microlaser drilling is one of the most common and frequently used laser processes by industry. The wide variety of laser source types makes it possible to process a diverse range of materials (metals, ceramics, semiconductors, polymers, organic materials, etc.) with unprecedented reproducibility, accuracy, and speed. Microdrilling is prominent in many industries, such as automotive, aerospace, and electronics, and even for laser surgery and in the food industry. For example, the ability of this process to drill high-aspect-ratio holes down to the micrometer scale has recently led to the development of new injection nozzles for the automotive industry, improving engine fuel efficiency up to 30%.1

Ultrashort-pulse lasers

Drilling smaller holes, increasing the drilling rate, enhancing the accuracy and quality of the holes, and reducing the energy consumption of the process led to a constant need to increase the output and quality of the industrial processes. This, in line with new, specific needs, leads to the regular development of new laser drilling techniques. One of the latest major innovations is the use of what are known as ultrashort-pulse lasers (USPs; see Editor’s Note) micromachining tools.

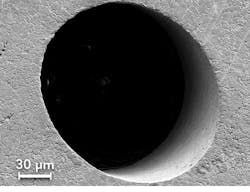

Ultrashort-pulse lasers deliver short and intense pulses of light, generally at high repetition rates (sometimes more than a hundred thousand pulses per second). The standout feature of these lasers is that they concentrate the luminous intensity of a pulse in an extremely short duration of time—on the order of a picosecond (10-12 s) down to a few tens of femtoseconds (10-15 s). Each pulse carries a certain amount of energy, but its briefness allows it to attain considerable peak power (up to several terawatts). In the case of USP lasers, the pulses are so short and energetic that they cause a near-instantaneous removal of the material being irradiated. Rather than removing material by having their energy absorbed as heat like more conventional lasers, the ultrashort pulses of these lasers cause the ionization of matter without thermal effects. This effect is known as cold ablation, allowing minimal internal stress, cracks, burrs, and other defects normally caused by heat absorption.2 USP lasers make it possible to quickly drill up to several thousand holes per second7 with diameters smaller than with any other process (a few micrometers; FIGURE 1). In addition, because this process requires little to zero post-processing of the machined material, high-speed lasers can provide a high production rate at lower costs,4 and the availability of increasingly compact and economical commercial USP lasers justifies their use for more and more industrial applications.

Laser beam shaping

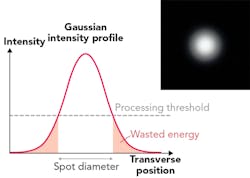

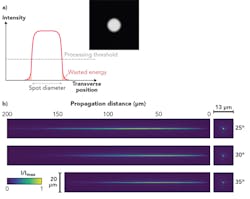

However, to truly maximize the effectiveness, quality, resolution, and efficiency of the process, it is necessary to apply a laser beam shaping technology adapted to the given application. A laser beam naturally has a non-uniform transverse energy distribution (FIGURE 2), which can lead to unnecessary energy losses, inaccuracies, and drilling irregularities. The type of material, the parameters of the holes, the quality of the drilling, and the production rates are all factors to be taken into account, and require optimization of the way in which the intensity of the laser pulses is distributed in the material being treated.Another frequently used shape is the Bessel beam, which enables the propagated energy to be intensely focused in a small but elongated zone over a long distance (FIGURE 3b). It is therefore particularly useful for the drilling of small-diameter holes (sometimes under a micrometer in diameter) with a high aspect ratio (holes with a depth-to-diameter ratio much greater than 10:1). This shape is notably used for the machining of transparent materials8 such as glass or sapphire. For more specific applications, it may be necessary to produce beams of more specific geometries, such as for machining photonic crystals or electronic microcomponents using mask-free lithography.

It is therefore necessary for optimization of the process to integrate a laser beam shaping unit in laser microdrilling systems. There are several types of beam shaping technology, such as refractive optical elements (ROEs), diffractive optical elements (DOEs), and spatial light modulators (SLMs). These technologies are typically used on an industrial scale, but they tend to be limited in terms of the type of shapes that can be obtained, suffer from a shallow depth of field (useful depth for drilling), and may have a reduced efficiency and a high price, depending on the application.

More recently, Multi-Plane Light Conversion (MPLC) technology provides a great amount of freedom in terms of beam shaping while presenting a high conversion efficiency (>95%). Developed by CAILabs since 2013, MPLC technology has achieved record results in shape parameters, depth of field, and energy efficiency. It makes it possible to generate standard shapes for the laser industry, such as flat-top and Bessel beams (FIGURE 3), as well as customized shapes for more specific applications, regardless of the wavelengths used. In addition, it offers new features such as the combined shaping of several beams, enabling the generation of complex shapes.

In the future

The constant evolution of USP laser sources, especially in terms of power, efficiency, and cost, makes USP laser microdrilling a process that can be used by an increasing number of applications. Long reserved for prototyping and micromachining applications with small production volumes, this technique is increasingly used as a top method for a growing number of applications on a larger scale, such as the manufacturing of arterial stents, OLED panels, and injection heads9 with greater and greater productivity. To ensure sufficient production rates with optimum machining quality, laser beam shaping maximizes the efficiency of the process. This is why it is necessary to have a beam shaping technology that is able to meet the challenges of new microlaser drilling applications, accompanying the evolution of the process.

REFERENCES

1. M. Mielke, Laser Focus World, 49, 11 (Nov. 2013); http://bit.ly/2RJY0eg.

2. K. Sugioka and Y. Chang, Light Sci. Appl., 3, e149 (2014); https://go.nature.com/2UN2ouN.

3. K. Sugioka, Nanophotonics, 6, 2, 393–413 (2017); http://bit.ly/2MTc1p6.

4. S. Sullivan, Industrial Laser Solutions, 31, 3 (May/Jun. 2016); http://bit.ly/2Gvpr9w.

5. E. Mottay, Industrial Laser Solutions, 32, 4 (Jul/Aug. 2017); http://bit.ly/2TIrRFP.

6. K. Fuse, Laser Tech. J., 12, 2, 19–22 (Apr. 1, 2015); http://bit.ly/2MYpLz2.

7. M. K. Bhuyan et al., Appl. Phys. Lett., 97, 081102 (2010); https://doi.org/10.1063/1.3479419.

8. F. Courvoisier, J. Zhang, M. Bhuyan, M. Jacquot, and J. M. Dudley, Appl. Phys. A, 112, 29–34 (2013); http://bit.ly/2Gs6wwq.

9. B. Peatman, Industrial Laser Solutions online (May 3, 2017); http://bit.ly/2RMhgaQ.

SAMI LAROUI ([email protected]) is a pre-sales engineer at CAILabs, Rennes, France; www.cailabs.com. There, he contributes to the development and commercialization of innovative optical solutions that optimize the quality and performance of laser machining processes.

Editor’s Note: The Industrial Laser Solutions International Editorial Advisory Board decided, by consensus, to use the term ultrashort-pulse (USP) lasers for industrial laser material processing with pico- and femtosecond pulses. It may be more common to see ultrafast-pulse (UFP) lasers used in some markets, but Dr. Geoff Shannon (Coherent), a leading femtosecond process developer and ILS Editorial Advisor, makes a good case for the USP laser acronym: http://bit.ly/2HZD9Ed.