In manufacturing displays, automotive windshields, and smart windows, for example, many features and functions require selective and precise ablation of conductive or low-emissivity coatings, as well as precise and flexible cutting of substrates. The challenges in laser processing of such very large and free-shaped glass substrates is to meet the requirements of precision and cycle time in 24/7 production environments.

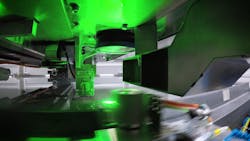

Recognizing this, 4JET microtech (Alsdorf, Germany) has tackled these challenges with its GLASS-LINE product line, which comprises laser systems for patterning thin-film coatings and for separating glass based on the company's PearlCut process.The company's large three-dimensional (3D) patterning solution enables removal of thin-film coatings such as transparent conducting film or low-emissivity coatings on large curved glass sheets, such as windshields or other transportation glass substrates. A new system covers a 3D processing volume of 1000 × 1000 × 300 mm3, and can create tracks at a resolution down to 100 µm as needed to produce electrical features or deleted coating areas to enhance RF transmission or to enable camera operation. The 3D XL solution is designed as an inline system, matching production line speeds of OEM automotive glass lines.

4JET is offering a platform for switchable glass applications (smart windows), providing high-speed, resolution and accuracy at the same time. Scribing of functional thin-film coatings on flat glass substrates with a size of approximately 2 × 3 m2 is possible. Scribe resolution goes down to a 10 µm track width, making the features invisible to the eye. Furthermore, its high-speed patterning feature, in combination with multiple parallel scan heads, provides a rapid cycle time, making the platform a very cost-effective tool for manufacturing architectural glass products.The 4JET Group combines two companies. 4JET Technologies specializes in laser systems for cleaning, ablation, and modification of delicate technical surfaces. Key markets include the automotive and tire industry. 4JET microtech specializes in micromachining solutions for cutting and drilling of brittle materials such as glass, as well as solutions for thin-film ablation. Established in 2006, the group now employs a team of more than 130 employees at its headquarters in Alsdorf; an assembly plant in Eschweiler, Germany; and a micromachining job shop in Prutting, Germany, as well as in the U.S. and China.