EDM shop adds laser capabilities

Laureen J. Belleville

Auniquely devoted wire electrical-discharge-machining (EDM) job shop that provides a high level of service to a wide variety of industries-that’s how Xact Wire EDM Corp. (www.xactedm.com) defines itself. John Dora and Jeff Gubbins established the company in 1984 with just each other, one wire EDM machine, and the belief that to succeed they needed to listen closely to their customers, constantly hire and train good people, frequently acquire new advanced technology, and always strive to improve and move into new application areas. Today the company boasts 55 employees, 34 wire EDM machines, six high-speed small hole machines, and one laser marker.

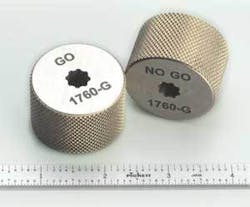

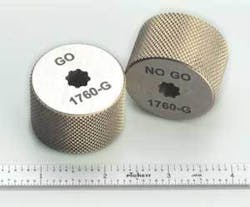

The company is headquartered in Waukesha, WI, and operates a fully equipped branch location in Cary, IL. While the company’s original focus was the tool and die and molding industries, the business has now transformed to mostly medical and other industries with precision metal parts (see Figure 1). Its current capabilities include die components, mold details and electrodes, production for medical/surgical/dental, high-precision small wire diameters, up to 30 degree taper angles, automatic threading, large workpieces, auxiliary rotary spindle EDM, file transfer/translation, CMM, video inspection, and small hole EDM.

Two years ago the company purchased its MicroLase marker from Schmidt Marking Systems (Niles, IL; www.gtschmidt.com) with the intent of bringing in-house some of the marking applications that it had been subcontracting. “Turnaround became too critical,” says Troy McGroarty, the company’s quality assurance manager. “And being able to define the parameters for marking fonts and such became increasingly difficult to communicate to contractors.” Gubbins adds that speed is what got him interested in the laser: “We didn’t want to lose a day or two sending laser marking out. Speed is one thing we have that foreign competition doesn’t have.” Xact is using the laser primarily for three major functions-marking part/ID numbers, company logos, and symbols-as well as arrows and other marks on in-house tooling and fixturing.

The learning curve for the laser was minimal: after about only one-half day of training the company was up and running the laser. “The neatest thing I’ve seen Troy do [with the laser],” recounts Gubbins, “is create different colors on a piece of stainless steel by varying the frequency,” (see Figure 2). McGroarty explains that the system has varying power range so that the user can make a rather deep mark in the component or a very clear mark without raising or removing any material and creating any form of indentation-just effecting a color change. For certain applications this feature can be critical for maintaining geometrical and dimensional tolerances and still mark the part.

A significant amount of the laser usage is for marking medical components, gages, and fixturing, most of which are stainless steel. An interesting application requires labeling the matrix for DNA testing, which involves marking company logos and row and column numbers on anodized aluminum fixturing for DNA test tubes. However, other applications involve materials such as tool steels, carbide, tungsten, and brass for other markets as well as proprietary material for the aerospace industry.

By comparison, the marking application for the aerospace industry is “not all that glamorous,” reports McGroarty. Raw aerospace material is brought to the company in very large chunks and is cut into smaller pieces for further processing. When it comes time to mark, “we’re actually transferring ingot numbers and heat numbers from the parent material onto smaller components as they move through the machining process. It’s a very scientific and formatted system,” he says.

Although the company runs three shifts daily, the laser is run on an as-needed basis. “We’ve recently added personnel around the clock in the quality department,” notes McGroarty, “and those are the people that run the laser. So at various times throughout the day the laser can be set up and run. And set-up can be as little as one to two minutes for this machine, which is amazing for us.”

In the last five years, business has increased significantly; 9/11, the Internet bubble bust, and competition in China all converged to make things a bit challenging, according to Gubbins. “But through all that,” he notes gratefully, “we never laid anyone off. We still worked some overtime, but we didn’t have any backlog. Work came in and went right out pretty fast.”

Gubbins attributes this renewed success to the focus on medical device markets and aggressively pursuing leading-edge wire EDM projects. “We’ve got projects that have been around for a number of years for some customers and those are starting to take off for them. So volume with existing customers is also increasing,” notes McGroarty. Additionally, Xact has a number of contracted laser services that are performed for customers specifically without doing any wire EDM. “We probably have about five steady jobs for it,” says McGroarty. “This is new, other business that we didn’t have before we had the laser.”

The upswing in business can also be attributed to a more aggressive, focused marketing campaign, which involves exhibiting at a number of medical design shows, design to part shows, and job shop shows. Utilizing digital technology also has been beneficial, as a professionally designed website that includes text, photos, and video (“Winner’s Circle” with Terry Bradshaw) has drawn new customers. Indeed, when you “Google” wire EDM, Xact Wire EDM Corp. is the number one return. After visiting the website, says Gubbins, “people become very interested in meeting with us and have confidence that we can meet their wire EDM needs. People look at us on the web, then view the video, and ultimately end up calling us.”

Realistically, Gubbins believes that the wave of work brought on by the medical industry will eventually crest, although that may be years away. In keeping with the philosophy of moving into new application areas, he’s already trying to figure out what the next “hot” market will be: “We need to determine what that will be and figure out how to apply our EDM machining process to that field.”

Wire EDM is a method for cutting conductive materials with a thin electrode that follows a programmed path. The electrode is a thin wire. Typical diameters range from 0.004 inch to 0.012 inch, although smaller and larger diameters are available. The hardness of the workpiece material has no detrimental effect on the cutting speed. There is no physical contact between the wire and the part being machined. Rather, the wire is charged to a voltage very rapidly. This wire is surrounded by deionized water. When the voltage reaches the correct level, a spark jumps the gap and melts a small portion of the workpiece. The deionized water cools and flushes away the small particles from the gap.

What is wire EDM?

Wire EDM can be accurate to +/-0.0001 inch. No burrs are generated. Because no cutting forces are present, wire EDM is ideal for delicate parts. No tooling is required. Pieces that are more than 16-inches thick can be machined.