Temperature fluctuations, shocks, scratches, and impacts affect tools and machines exposed to persistently heavy loads in industry. Welding equipment, for example, is under the constant influence of spark flight, dust, and heat during used on construction sites. In addition to the devices, their marking must also withstand such effects, as it is essential for the identification of a device. In order to maintain high-quality type plates over the entire service life, it is important that they are particularly resistant. A lack of protection and extreme loads can lead to damage to the surface up to unreadable type plates.

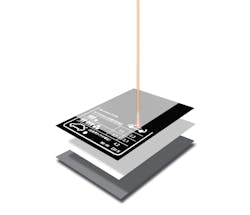

Recognizing this, Schreiner ProTech has developed an optimal solution for the challenges of industrial influences: the HighResist (CLF HighResist) color laser film. It is long-term tested and specializes in use under harsh conditions. It combines maximum stability and flexibility at the same time. In addition to the particularly high-temperature, scratch, and weather resistances typical of the color laser film, CLF HighResist is also characterized by a high scratch resistance and thus resists high mechanical stresses. The strong UV and adhesion resistance are further advantages of this solution. Optionally, safety and originality protection features such as microscripting can be integrated, and individual design is also possible.The labeling is done with various near-infrared lasers (Nd:YAG, Nd:YVO4, Yb fiber) and produces a very good contrast. The labeling process takes place inside the material composite below the protective laminate and is thus emission-free. Format cutting and labeling can take place in just one operation. When using pre-punched CLF HighResist, the process is completely emission-free and suitable for cleanroom applications.