Black, corrosion-resistant marking for the medical device manufacturing industry is now a hot application. This unique laser mark, frequently used for stainless steel implantable devices and tools, survives multiple passivation and autoclaving cycles.

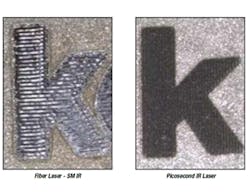

This black mark is generated using ultrashort pulse durations from a picosecond laser that imparts energy to a material surface with almost no thermal effect. Unlike the heat-generated annealed marks made with fiber lasers, marks created by picosecond infrared (IR) lasers are extremely high contrast periodic nanostructures with antireflective properties that make the marks appear deep black against their surroundings; they are restructured surface material rather than an oxide layer, making them highly resistant to bacterial growth, passivation, corrosion, and autoclaving. In addition, the processing window for developing the marks on stainless steels, aluminum, and titanium is significantly wider than that of traditional fiber lasers. Picosecond lasers also offer excellent marking capabilities on polymers often used in medical devices. They are the premier choice for robust, smooth, and permanent UDI-compliant dark marking for medical device manufacturers.

The picosecond laser is integrated into a custom-built CDRH Class 1 system designed for a specific part or range of parts. System features may include a galvo scanning head, a bar code scanner for job load, four or more axes of motion, and machine vision for part recognition and mark placement.

AMADA Weld Tech (Monrovia, CA) manufactures equipment and systems for laser welding, laser marking, laser cutting, and hermetic sealing. The company serves a wide range of markets, including medical devices, battery, aerospace, automotive, and electronic components. For more information, please visit amadaweldtech.com.