Three years ago, a major American manufacturer of automotive components asked laser marking machine maker Lasit (Torre Annunziata, Italy) for a laser marker to track bevel gears and automobile differentials. The manufacturer needed precision and reliability, along with productivity and the ability to check the quality of themarked Data Matrix codes.

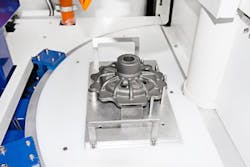

An automotive component ready for marking is shown.

Lasit created Rotomark X, a customized marker capable of meeting all these requirements. It features a steel structure marker equipped with X and Z axes, a rotating table, and a lateral video camera that inspects, recognizes, and reads the marked Data Matrix code. Despite the higher accelerations, the system remains stable and secure, even in the event of accidental movements or shocks since it is also equipped with pneumatic, software-controlled grippers that block the rotating table during marking.

The Rotomark X laser marker is shown.

With regards to productivity, the customer requested the marking of many pieces in less time. This machine has an X axis for transverse movement on the plane, so the marking area increases to 150 × 650 mm. The machine works in downtime, thanks to its mechanical cam rotating table.

Regarding marked Data Matrix quality control, Rotomark X has a vision system that offers a broad, accurate perspective. The marker also has an integrated circular illuminator with an intensity regulator, so everything is connected to software for clear display of checks on the screen.

For more information, please visit lasitlaser.com.