Femtosecond laser sources have revolutionized materials processing with their ability to provide both power and control. To fully use the available power and translate it to high-throughput processing, femtosecond lasers must be used in conjunction with high-speed motion systems such as galvo and polygon scanners. The spatial overlap of consecutive laser pulses on the workpiece is a critical parameter for optimal machining quality, whether cutting, engraving, surfacing, marking, or scribing.

While conventional methods typically result in inconsistency and overprocessing of complex profiles due to the acceleration and deceleration of the motion system, pulse-on-demand technology allows individual pulses or controlled pulse bursts to be placed with precision and evenly spaced, regardless of variations in motion speed. Alternative approaches such as skywriting may be used to produce consistent results, but these also introduce a significant amount of dead time to the process, which results in lower overall process speeds and longer cycle times.

Meanwhile, the extremely short pulse width of the femtosecond laser source can virtually eliminate heat diffusion to the surroundings of the processed region, provided the pulse width is shorter than the time taken to transfer heat to the bulk material. The process is commonly referred to as cold ablation. And the pulse-on-demand feature effectively allows the user to control the repetition rate to avoid heat accumulation in the material, while maintaining a constant pulse energy. This minimizes the formation of a heat-affected zone (HAZ), enabling ultra-high-precision micro- and nanofabrication of various components with high throughput and repeatability.

One example of a femtosecond laser source, the LXR series ultrashort-pulse (USP) laser developed by Luxinar, will allow entry into new markets and applications in a diverse range of industries previously inaccessible with carbon dioxide (CO2) laser sources. Sample processing using the technology is currently being carried out at the University of Hull (UK) in its department of physics and mathematics.

The Hull research group works extensively with laser material interactions and has explored various applications with Luxinar femtosecond laser technology, including flat cutting of metals, plastics, and composites; tube cutting of metals and biodegradable plastic materials for medical devices such as coronary stents; and high-quality bitmap marking.

Subsurface glass marking for the pharmaceutical industry

Glass marking is an application where the difference between femtosecond and conventional CO2 lasers is clear, and both systems are useful in different ways. The CO2 laser wavelength is absorbed so strongly in glass that the entire interaction happens at the surface. While this is an advantage in some applications where surface marking is desirable (such as head keepers in beer glasses), it makes it simply impossible to mark below the surface.

This is not the case with femtosecond lasers, which can mark in the bulk of optically transparent materials. Although glass is transparent at the laser wavelength, nonlinear absorption effects allow the formation of a dense plasma at the focal point, which then becomes strongly absorbing and produces marking in the volume of the material.

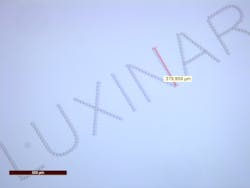

In this way, technology such as the LXR 120-1030 has successfully marked 0.5 mm below the surface of a piece of glass. The mark is made using closely spaced dots to form characters less than half a millimeter high (see Fig. 1). In fact, the marking is barely visible to the naked eye.

Potential applications include syringe and vial marking for the medical and pharmaceutical industries. Subsurface marking is particularly attractive in this setting, because the codes are indelible and not subject to wear or damage.

Glass cutting for the automotive industry

Thick glass cutting is an interesting application where femtosecond and CO2 lasers are used together. Traditional mechanical scribe and break techniques are still commonplace in this industry, or scribing and cutting can be performed using a CO2 laser alone. The quality of results, however, is not optimal in either case.

While both processes are quick and efficient, the glass edges are typically left with numerous microcracks. Traditional methods cannot easily produce curved shapes or rounded contours, which are often required for automotive rear view and exterior mirrors, for example.

Superior results can be produced using a femtosecond laser to scribe the glass. This process requires high energy, which may be delivered as a single pulse or as a fast, high-energy burst. A CO2 laser supplies thermal energy, which initiates cleaving along the scribed line. The glass is separated cleanly with little or no damage due to microcracking at the edge, and curves, straight lines, and closed contours can be produced (see Fig. 2).Scribing metal foils

Another application making use of the USP laser’s precision is the scribing of metal foils for RFID and mobile device antenna applications, which commonly use aluminum and copper. The laser selectively removes the conductive metal layer from a carrier or substrate material—typically paper or polyimide—to fabricate antennas and other flexible circuit components.

The constant drive toward miniaturization requires narrow lines scribed as close together as possible. But because adjacent lines must be electrically isolated from one another, the metal must be removed very cleanly from the substrate—with no damage to the surrounding area, no burrs, or rough edges that may form short circuits between device features. The LXR 120-1030 can scribe lines in aluminum foil that are 50 µm apart (measured from center to center) without significant damage to the carrier material. This result would simply not be possible with a CO2 laser.

Cutting and drilling carbon fiber composites

Carbon fiber composites are now commonplace in the automotive and aerospace industries. While these materials exhibit desirable properties such as a high strength-to-weight ratio, drilling to form rivet holes for joining parts and other machining is problematic. Mechanical processing can result in delamination and matrix damage, as well as considerable tool wear and breakage.

On the other hand, their anisotropic thermal and optical properties present significant problems for conventional laser machining. The thermal conductivity of the fibers is much higher than that of the epoxy matrix, while the matrix material is vaporized more readily. Laser processing often leaves the fibers exposed as a result, compromising the strength of the material around the cut.

This is where the femtosecond laser comes in. Heat diffusion is greatly reduced, so cutting or drilling can be accomplished leaving the epoxy resin intact in the surrounding material. This means holes can be drilled and features cut out without compromising the strength of the carbon fiber sheet, which is one of the key reasons for choosing this material in the first place (see Fig. 3). The avoidance of heat accumulation is critical.Samples of carbon fiber composite were cut successfully using the LXR 120-1030, operating the laser at a demand frequency of 1 MHz to maximize the available pulse energy. Pulse-on-demand capability was used to control spatial overlap and limit the actual repetition rate seen by the material. Overheating is minimized, which reduces HAZ and limits vaporization of the epoxy resin alongside the cut. This allows the structural integrity of the material to be retained.

Femtosecond laser technology has opened a variety of new processing opportunities for industries including automotive, electronics, and pharmaceuticals, which are not possible with CO2 laser sources.

With features such as high beam quality, flexible control, pulse on demand, and burst mode selection for process optimization and high throughput, as well as a short pulse width to minimize thermal damage, femtosecond laser technology is attractive for many high-precision applications.