JOSH BROWN

Laser plastic welding is an ideal bonding solution for most medical device applications. It is fast, clean, and precise, but limitations in weldable plastic color combinations can often create headaches and difficult compromises between medical device marketing, engineering, and manufacturing teams. This article will explore new options in laser and material technologies that allow for a broader range of color combinations, including highly sought after but difficult-to-weld white and clear plastics.

Transmissive and absorptive properties in laser welding

Before getting into the specific challenges and approaches of welding these color combinations, it is helpful to understand how laser plastic welding works. There are two primary forms of laser plastic welding this article will discuss:

- 1 μm or through-transmission laser welding

- 2 μm or transparent laser plastic welding

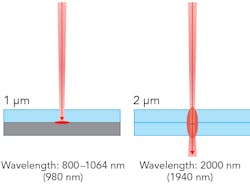

The 1 μm vs. 2 μm terminology refers to the wavelength of the laser being used and how the different wavelengths interact with and heat up the plastics to be bonded. FIGURE 1 demonstrates how these two types of welding work.

1 μm welding principle

In 1 μm or through-transmission laser welding, an upper transmissive layer and a lower absorbing layer are required. The laser penetrates the upper (transmissive) layer and is then absorbed into the lower (absorbing) layer. The heat absorbed by the lower layer is then transferred to the upper layer via conduction because the layers are in tight mechanical contact.

With the upper transmissive layer, most thermoplastics in their natural state are fully or somewhat transmissive in the 800–1064 nm laser wavelengths, and with the lower absorbing layer, absorptive properties are most commonly achieved by adding carbon black into the compounded plastic. Carbon is an organic compound and readily absorbs the laser energy—however, carbon will make the plastic visually black, which is often not desired by medical companies.

2 μm welding principle

In 2 μm welding, the goal is to be able to weld two transmissive pieces of plastic without the need for additives or an absorbing layer.

Laser energy is still required to be absorbed into the plastics in order to heat the parts up to a melt flow temperature. Without laser-absorbing additives like carbon to absorb the laser energy, this is overcome by using a higher-wavelength laser whose energy is partially absorbed into the plastics.

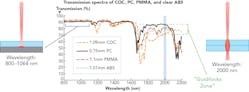

This laser wavelength range is often referred to as the Goldilocks Zone, where roughly 20–30% of the laser energy is absorbed by the plastic while still transmitting about 70–80% of the laser energy through the bulk of the layers (FIGURE 2).Color combinations for 1 μm welding

While natural- or clear-to-black is the simplest combination, it is possible to weld many color combinations with a 1 μm laser. FIGURE 3 shows the degree of difficulty for different color combinations; let’s explore the reasons for the difference in difficulty as well as the solutions to each.Natural-to-black

The simplest color combination for 1 μm welding is the standard natural-to-black combination. The natural (often optically clear) upper layer will have the highest transmission rate and the lower carbon-filled layer will have the highest absorption rate.

This allows for the fastest cycle times, typically the cheapest material compounds, and the widest and most forgiving process window.

Black-to-black

Surprisingly, welding black-to-black materials is actually quite simple and easily achieved (FIGURE 4). In this color combination, the lower layer is still doped with carbon to create an absorptive and optically black color, but the upper layer is doped with a very dark red or green dye. The colored dyes are so dark they appear visually black, but still allow laser radiation to penetrate the parts.Color-to-black

Moving up the difficulty ladder we come to a desired color, which can be most any color, mated to a standard carbon-loaded black base layer (FIGURE 5).This color combination uses inorganic colored dyes in the upper that do not absorb laser energy. Many plastics dyes will work adequately for achieving your desired color, but it is recommended you work with an expert to ensure this is the case.

Color-to-different color

As mentioned in the last two examples, creating a transmissive upper layer is quite straightforward using colored dyes, many of which still allow for laser penetration. The added difficulty comes in the lower layer because we can no longer utilize the well-absorbing carbon black.

In order to achieve a colored, yet absorbing lower layer, special laser absorbing additives must be utilized. These additives, when doped into the plastic, absorb the laser radiation effectively, although not as effectively as carbon, resulting in some absorption loss and slightly increased cycle times. These additives also give the plastics a slight green or gray tint.

Color-to-same color

What makes this combination more difficult to realize is that the laser-absorbing additive in the lower layer, as mentioned above, has a slight green or gray tint. This makes exact color matching more difficult, as the slight tint from the additive needs to be accounted for when color matching (FIGURE 6).It is also worth noting that while many laser-absorbing additives are biocompatible, this requires an additional layer of scrutiny for medical devices that require biocompatibility or special fluorescence characteristics.

Natural-to-white

In this case, the natural upper layer is typically of little concern, as it will have a high transmission rate. The difficulty comes with the white, lower layer.

In order to achieve a white color, plastics need to be doped with titanium dioxide (TiO2), which reflects laser radiation—making it more difficult to get proper absorption of the laser. In order to get enough absorption, white plastics require special laser-absorbing additives that need to be loaded into the plastic to overcome the reflective properties of TiO2.

While stark whites can be achieved with laser additives doped into them, there is a tradeoff. Starker white plastics need more TiO2 and less laser additive, leading to higher reflectance and a narrower process window. Stark white plastics are very possible, but they come with more restrictions in the design of the joint to accept the laser energy properly and also typically slower cycle times.

White-to-white

The most difficult color combination to achieve is white-to-white. In this case, the reflectance of the TiO2 now not only needs to be accounted for in the lower layer, but also the upper layer. The TiO2 in the upper layer will reflect some laser energy-lowering transmission.

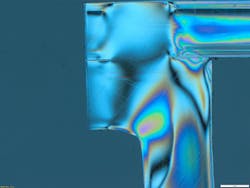

In this instance, the loading of the TiO2 in the upper layer needs to be kept to a minimum to retain some transmission in the plastic upper layer. This can make color matching more difficult, but by no means impossible.

White-to-white welds (FIGURE 7) are best achieved where the upper layer is as thin as possible, typically under a few millimeters in thickness.Clear- or color-to-gray

This combination is not included in the upper chart in FIGURE 3, but it is very much worth mentioning. In terms of difficulty, this combination would fall right in the middle of the difficulty range.

Gray materials are typically created by loading the plastic with both carbon (black) and TiO2 (white), which offset each other to create gray. The higher the carbon and the lower the TiO2 loading, the darker the gray and the higher absorption, making for an easier weld. The lower the carbon and the higher the TiO2, the lighter the gray, resulting in less absorption and a narrower process window.

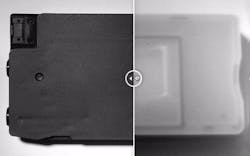

Clear-to-clear using 2 μm

In this instance, it is necessary to fully break away from the color difficulty chart in FIGURE 3. That chart is intended to instruct primarily on how color combinations impact the 1 μm, through-transmission laser welding process.

In most cases, the best way to achieve a clear-to-clear weld is to use a 2 μm welding process (FIGURE 8) because no additives are required. This solves a lot of problems for medical device companies that have to qualify materials for biocompatibility, fluorescence, optical appearance, and of course aesthetics. It’s also cheaper, as additional additives are not needed—and family molds can be used because both plastics can be exactly the same.It is, however, important to note that the 2 μm welding process is very different from the 1 μm process and special design considerations need to be accounted for. Here are some general guidelines that can help to get started:

- Upper-layer thickness should not exceed 3.5 mm (this is dependent on plastic type)

- Bottom layers do not have to be clear—only transmissive—and they can also be colored or translucent

- Glass-filled upper layers are not advised

- There are some limitations on the ability to clamp the parts, as in most cases glass must be used. Glass is difficult to machine if the application has curved or three-dimensional features, although there are methods for getting around this.

Clear-to-clear using 1 μm

It is also possible to weld clear plastics using 1 μm lasers. This is achieved by either doping the plastic with a laser-absorbing additive or applying a liquid solution of the additive (in a solvent base like alcohol) at the joint interface. There are two approaches to this method:

This approach, however, has some drawbacks that can be difficult to overcome, including:

- The solution must be applied consistently to the joint, most often via pad printing or spray nozzles, adding complexity to the manufacturing process.

- The solution burns off typically after a single pass of the laser beam, meaning only one pass of the laser can usually be made, limiting this process mostly to lap joints that do not require collapse.

Summary

Abilities to achieve various color combinations with laser plastic welding have come a long way since the advent of the technology in the 1970s. Thanks to advancements in material sciences and laser technologies, companies are no longer limited to natural-to-black colors to realize the profound advantages of laser plastic welding.

While certain color combinations can add difficulty to an application, nearly every single combination has now been realized and successfully deployed in high-volume manufacturing scenarios. Every combination comes with its own nuances, approaches, and limitations, so it is advised to speak to an expert who can provide contacts at the right material companies, as well as help with design advice and limitations for the ideal colors.

JOSH BROWN([email protected]) is Global Sales Manager, Laser Plastic Welding at Dukane, Aumsville, OR; dukane.com.