Since submitting the draft for Part I, I became aware of several new players on the ultrashort-pulse (USP) laser side. As of this writing, prior to the SPIE Photonics West exhibition, I am sure I will find new companies involved in some aspect of the USP world. Some of this new data will surely be shared in a future publication. For now, the following information should serve as a look at what is available in the industry. I know there are companies I missed mostly because I am not aware of them, and I always welcome input so I can update my database.

In this installment, I will look at some components of USP processing other than the laser. In particular, optics and beam delivery systems transfer the beam to the target, shape and condition the beam along the way, and provide safety to the operators. Without the proper optics and beam delivery, the laser is just a ‘light bulb,’ so this is a crucial aspect of USP laser processing.

However, beyond the optics, system integration has to include motion, vision, robotics, software, safety, and many more considerations. High-precision processing with USP lasers also requires high-end integration of all of the mentioned components. Just a few years ago, many established system integrators did not want to build or did not have experience building USP laser systems—now, there are a number of companies that are integrating lasers for either broad application use or for very specific applications. Finally, the actual use of the laser systems is crucial to promoting the technology and developing new applications. To tie it all together, I take a look at a number of U.S. contract manufacturers providing USP laser processing services.

Optics

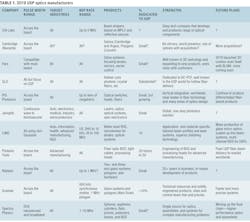

Very few optics companies deal exclusively in USP lasers or even consider the USP laser market to be a large part of their business. A number of ‘standard’ optics companies claim to be in the market, but there was nothing on their websites to indicate this to be the case. With the exception of demanding applications, ‘standard’ optics can be used for pulse lengths above 200 fs (at very short pulse lengths, the broadband nature of the light must be considered), so I am sure marketing types would take this as evidence of being in the USP business. The companies represented advertised their involvement in the market either at recent conferences/exhibitions or in publications, and seven of the 11 listed companies responded to my questionnaire. Most of the optics specific to USP lasers involve either moving the beam extremely fast in order to elevate the usable repetition rate of the laser or splitting the beam to more efficiently use higher pulse energy.

TABLE 1 shows a representation of companies supplying optics for USP laser applications. As can be seen, none have business models where USP lasers are the dominant part of their activities, but all those represented thought there was good growth potential in this area. As done with the previous section on lasers, I chose a few representative companies from this table, and the following tables, to discuss in more detail. A number of companies appear in more than one table.In the field of optical components, LIMO (Dortmund, Germany; www.limo.de) is one of the world’s major suppliers of glass cylinder lenses, thanks to its highly efficient wafer-based manufacturing technology. The company specializes in precision optics of all diode types and all power classes. With wafer sizes of up to 300 mm, it is possible to produce tens of thousands of lenses from high-grade glass and crystal in a single-step process with consistently high quality. It produces custom optics for high-end applications and is primarily interested in developing multichannel beam delivery systems for USP lasers.

Photonic Tools (Berlin, Germany; www.photonic-tools.de) is a team of physicists, engineers, and businesspeople with experience in the laser and beam delivery world, having started and run previous companies. They know the market and technical challenges and offer custom products for USP lasers. The company’s ultrafast fiber-optic cables are the flagship product, but a range of new products are being developed. The USP market is a major part of its future plans.

Scanlab (Puchheim, Germany; www.scanlab.de) is a company that started about 20 years ago and now enjoys a prominent position in the world of fast beam motion. It provides scanning solutions across the board in wavelength, pulse length, and power. Its Next Scan Technology (Evergem, Belgium; www.nextscan.com) division is focused primarily on rapid polygon scanning for USP laser applications. In fact, integrated packages containing both polygons and galvanometers (also known as galvos) can be purchased as standard or custom products. Standard galvo-based scanners are available in 2D and 3D and, in fact, the company’s parent organization also owns Raylase (Wessling, Germany; www.raylase.de), another company in the list, although in principle the two companies operate independently. In general terms, galvanometer beam steering attains 100–150 rad/sec in a standard configuration and can achieve 1000–4000 rad/sec in a custom configuration, equilibrating to hundreds of kilohertz. Polygon beam steering is typically in the range of 100 ns, which is about 1–3 MHz and with hybrid configurations, the usable repetition rate can go to as high as 10 MHz.

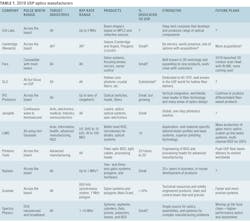

Systems

TABLE 2 shows a list of 20 USP system integrators, most with international business models who also do business in the U.S., 12 of whom responded to my questionnaire. Some of the companies listed—for instance, 3D-Micromac (Chemnitz, Germany; www.3d-micromac.com), PhotoMachining (Pelham, NH; www.photomachining.com), and Photon Energy (Amsterdam, Netherlands; www.photonenergy.com)—are involved in USP laser systems pretty much across the board application-wise, but they do not manufacture lasers. Lasers are purchased from laser manufacturers discussed in my last article. The choice of laser for systems manufacturers depends on a number of things, such as the relationship with the laser vendor, cost, performance, and support, but probably the biggest component is the laser on which the application is developed. End users like to minimize risk by integrating known lasers into their manufacturing machines where possible. As will be discussed later regarding TABLE 3, a number of the listed USP laser systems providers also do contract manufacturing or at least process development in their job shops or applications labs, and the lasers used in these lab tests would probably be used unless there is a good reason to do otherwise.Companies like Clark-MXR (Dexter, MI; www.cmxr.com), IPG Photonics (Oxford, MA; www.ipgphotonics.com) and TRUMPF (Ditzingen, Germany; www.trumpf.com) deliver standalone lasers and totally integrated laser systems. A number of the companies listed are and always have been ‘laser’ companies, while there are also a number who have a substantial present and also historical business other than lasers—for instance, TRUMPF, GF Machining Solutions (Geneva, Switzerland), and DMG Mori (Bielefeld, Germany; www.dmgmori.com). Most USP systems providers will address a large number of applications and materials, but a few are much more concentrated. Glass (or any hard, brittle material with poor heat expansion properties) is very hard to work with and is an excellent material for processing with USP lasers, especially on very small devices that do not require a great deal of material removal. LightFab (Aachen, Germany; www.lightfab.de), e-Laser (Vilnius, Lithuania; e-lasers.com), and BOLD Laser Automation (Bedford, NH; www.boldlaserautomation.com) are all concentrating on primarily this material.

Let us take a look at a few companies in particular. TRUMPF is a multi-billion-dollar company located in Germany and has been in the machine tool business for decades—the laser division is over $1 billion itself. They provide the lasers (some developed in-house and also through their acquisition of Amphos [www.amphos.de], another German company) and also build systems. TRUMPF’s primary interest is in selling systems where a large number of one type, or of some standard configuration, can be sold. Customization with larger companies is usually less desirable and more costly. TRUMPF has extensive applications knowledge, although even within the laser division, the contribution of USP lasers is still quite small. TRUMPF systems and lasers tend to be very high reliability and high throughput, and they are also on the higher end pricewise. GF Machining Solutions, another large company with a long history, is a Swiss company historically involved in the machine tool industry. The company’s target industries are tooling, mold, and die for auto and electronics. It has extensive applications knowledge within the above fields. It has developed USP laser tools in-house and also have expanded through its acquisition of Microlution (Chicago, IL). Currently, it works mostly with metals, but it can work with other materials. Its machines feature five-axis machining and multi-axis precision heads.

3D-Micromac, a very strong player in the precision laser systems business, makes laser tools with any laser pulse length and wavelength. The company has a large number of ‘standard’ platforms for the semiconductor, photovoltaics, medical device, microelectronics, and display industries. It also manufactures custom systems, including part handling. This is sometimes key, as frequently getting the parts on and off the laser tool takes more time and effort than the actual processing. 3D-Micromac has a worldwide presence and currently over 50% of its total business is dedicated to USP processing. LightFab is a company that deals almost exclusively with selective laser etching (SLE) in glass and glass-like materials. The SLE process is not a ‘pure’ laser process in that it needs a post-laser-etching step, but it allows features to be made that cannot be made in any other way. The process is like 3D printing in reverse and requires an otherwise-transparent, brittle material (fused silica, sapphire) and a laser with a variable pulse length between about 500 fs and 10 ps to dial in the correct setting for each application.

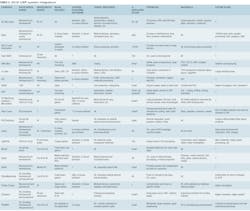

Job shops

TABLE 3 shows 12 job shops (or, if you prefer, contract manufacturers) located in the U.S. that are, or at least who say they are, involved in USP laser processing. Seven of these companies responded to my questionnaire, while two more responded that they cannot give any information. Of all the companies queried for the different areas, I had a lot of no-responses, but only two companies, both in this category, wrote back and refused to give any information. However, these two companies have been included based on their websites along with the ones who did not respond. Within this list, only Clark-MXR is exclusively USP. Four others are primarily ‘laser’ shops—Lasea (Angleur, Belgium; www.lasea.eu), Laser Light Technologies (Hermann, MO; https://laserlight.com), PhotoMachining, and Laserrod Technologies (Torrance, CA; www.laserrod.com). Four others have lasers, but their laser portions of the businesses are small, let alone their USP laser businesses: Johnson Matthey (London, England; www.matthey.com), Norman Noble (Highland Heights, OH; www.nnoble.com), OKAY Industries (New Britain, CT; www.okayind.com), and Pulse Technology (Carol Stream, IL; www.pulsetechnology.com). Two are primarily laser shops, but are a part of much larger entities—Resonetics (Nashua, NH; www.resonetics.com) and Spectralytics (Maple Plain, MN; www.spectralytics.com). Companies that are involved with larger entities or have laser processing as a smaller part of their overall business are marked with an asterisk (*). To me, the interesting thing is that all are involved in the medical device industry, some exclusively. There are many other job shops in the U.S. currently considering jumping into the USP arena or that have USP lasers already, but are only starting out—so this table is a representative sampling for now, as new shops will be joining the ranks almost on a monthly basis.PhotoMachining is a company I am very familiar with, as I was a partner there for over 20 years. They are totally devoted to laser processing and systems integration and have lasers in their job shop, from microsecond to femtosecond pulse length and from 248 nm in the ultraviolet (UV) to 10 µm in the infrared. Historically, a lot of UV and high-resolution processing has been done, which has shifted to mostly USP in the last five years. Customers are welcome in the applications lab for process development. Spectralytics started out as primarily a laser processing house, but they became a part of the Cretex (Elk River, MN) family of companies a few years ago. Cretex has been in the concrete business for decades, but decided a few years ago to diversify into the medical arena. Spectralytics gets a lot of business from ‘sister’ companies and has multiple locations, but still is itself basically a laser company. Some of its facility space is open to visitors, but most is not.

OKAY Industries has many processes in-house for mostly working with medical metals. In fact, about 90% of its work is done in 304 stainless steel. The company has looked at femtosecond lasers for stents and other things, but finds that with the right care, it can get results almost as good with fiber lasers and at much faster speeds and cheaper costs. So, it is almost exclusively focused on black marking of stainless steel, but this could grow into more applications as it gets accustomed to using USP lasers. While lasers are a substantial part of its business, it is not primarily a laser shop.

Norman Noble is another company that is not primarily a laser shop, even though lasers are a large part of its business. It has a large number of lasers as well as other manufacturing technology, and provides rapid prototyping, process development, technology assessment, validation, and production of mostly medical devices. The company will offer high-volume manufacturing of full devices, components, and subcomponents.

Conclusion

As can be seen from the data in the previous tables, the USP laser market is a vibrant and growing sector of the industry. While a great laser is necessary for successful application of the technology, it is not enough. System integration, including using optimized optics, is key to peak performance, and applications development is what really drives the industry. Some of the reviewed companies concentrate almost exclusively on USP lasers, optics, systems, and/or applications, while for others, lasers—and especially USP lasers—are currently only a small part of their business. However, these larger entities must see a great future in the USP arena, or they would not be investing.

As for the laser market in general, it is almost certain that picosecond lasers will replace nanosecond lasers in a large number of current applications as laser costs go down and production volumes rise. So, the effect on the overall market will not be as big as it might be, but nonetheless, lower costs and increased applications knowledge will open a wide range of new market areas.