JENS GAEBELEIN and JEROEN HRIBAR

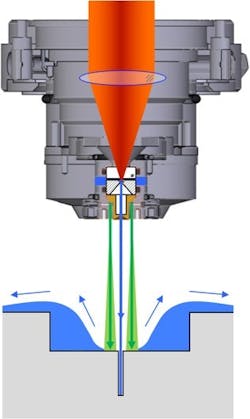

Liquid-jet-guided laser technology is more than 30 years old, but new technological advances are expanding its scope into industrial applications that require 24/7 production processes. A newly developed laser system using modern high-performance fiber lasers efficiently directs multikilowatts of power into tiny waterjets (FIGURE 1). In addition, operation and maintenance for these systems has been dramatically simplified.

In 1986, Aesculap-Werke (Tuttlingen, Germany) invented the first system guiding a laser beam to a workpiece by applying internal reflection inside a liquid column.1 In 1991, LASAG (Thun, Switzerland; now a Coherent-Rofin company) refined this principle by generating the liquid column using a waterjet nozzle and focusing the laser into the nozzle inlet.2 Building on the same principle, another refinement step was made in 1994 by B. Richerzhagen and then commercialized by Synova (Lausanne, Switzerland) in 1997, transforming the improvements into the process known today.3

Waterjet-guided laser challenges

In summer 2013, the founding engineers of Avonisys (Zug, Switzerland) were confronted with the challenge of machining deep micro-slots with a cumulated length of several meters into concave mold surfaces—a complex five-axis CNC-machining job that required uninterrupted, 24-hour laser machining on individual workpieces. Theoretically, this task could have been satisfied by liquid-jet guided laser technology that has been available in the market for many years. Unfortunately, it was rapidly discovered that this project was far from trivial and important challenges had to be overcome to successfully manage such a complex machining task.

This challenge led to the formation of Avonisys and was the starting point of an extensive development period in which many fundamental experiments were performed and existing theories were questioned, resulting in a completely new liquid-jet laser system.

Avonisys developments

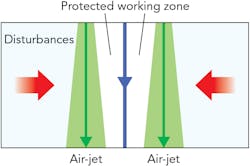

The first hurdle was finding a solution to keep concave workpiece surfaces free from water accumulation. For a technology that relies on guiding laser energy by internal reflection, it is understandable that a proper water-to-air interface is paramount. Existing methods in which an assist gas is directly enveloped around the waterjet through one mutual exit aperture were not suitable. The required pressure to remove water from the workpiece vaporized the waterjet—furthermore, lower gas pressure did not prevent the process from “drowning.”

Consequently, air-jet technology was developed and turned out to be a game-changer.4 In the air-jet process, a spaced-apart coaxial stream of air around the waterjet is controlled without interference to the waterjet until reaching the workpiece surface (FIGURE 2).An important aspect for robust liquid-jet laser machining is consistent high laser energy transmission without damaging the waterjet nozzle. Typical waterjet laser systems apply high-numerical-aperture (NA) optics that focus the laser in the nozzle inlet plane, regardless of nozzle diameter and laser properties.

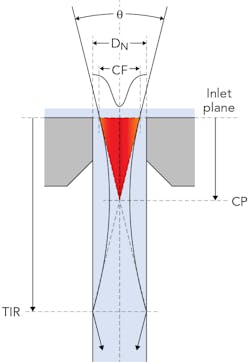

This did not seem to be the best approach, and in a quest to increase laser energy throughput and nozzle lifetime, Avonisys started a series of fundamental experiments that resulted in a dedicated laser head and geometric coupling method to achieve accurate and repeatable coupling of high-power laser beams.5 The experiments led to the following mathematical relationship:

CP = (0.5 × CF × DN)/(tan(θ/2))

Here, CP represents the coupling point of the laser focus as offset below the nozzle inlet plane, CF is a coupling factor representing an energized beam diameter (1/e2, 98%, 100%), DN is the nozzle diameter, and θ is the laser focus cone angle based on laser beam parameter product (BPP) and beam delivery optics geometry. Essentially, the equation describes how deep the laser focus cone can be placed into the nozzle without introducing laser energy, exceeding its damage threshold (FIGURE 3).The infrared paradigm

Today’s waterjet laser systems typically use green nanosecond YAG lasers, mainly due to considerations of low absorption of this wavelength in water. Avonisys engineers, however, found that outcoupling losses from high-NA optics play a far more significant role than the “believed and preached” effects of absorption properties of water. Rather than using green lasers simply because the effects of absorption are believed to be the key effect that limits power transmission, we found this to be of little relevance and instead developed a laser coupling method able to couple large amounts of laser energy and cut through thick materials.

Due to excellent laser beam quality and low maintenance characteristics of modern IR fiber lasers, Avonisys was keen on “forcing” as many applications to fit this laser type, mainly to keep the system setup simple and robust for industrial 24/7 usage. Today, the company can successfully cut thick materials with IR fiber lasers that were once considered impossible.

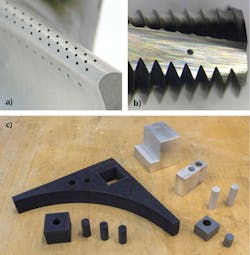

The redPOWER QUBE pulsed continuous-wave (pulsed-CW) fiber laser from SPI Lasers (Southampton, England) pairs particularly well with the Avonisys liquid-jet process.6 Using pulsed-CW fiber lasers compared to similar quasi-CW fiber lasers brings specific advantages for the liquid-jet process. Due to the higher CW output that can be modulated down to 1 µs pulses, it is possible to drill deeper micro-holes in hard materials such as Inconel and tungsten carbide and to make deeper cuts in aluminum and silicon using waterjet nozzles as small as 30 µm (FIGURE 4).“Installation of our laser with the Avonisys process was surprisingly easy,” says Mark Southwell, field service manager at SPI. “Literally minutes after connecting the laser for the first time, we were already laser-cutting material. This was a very positive surprise to me and not what I expected.” Meanwhile, Avonisys and its customers have installed various 1.5, 2, and 3 kW redPOWER QUBE fiber lasers at various customer sites in Europe and Asia.

Jet coherence vs. jet stability

A coherent waterjet is obviously a prerequisite for the waterjet-guided laser. Comprehensive research on increasing coherence of small waterjets (30–80 µm) was performed by Cadavid and Wüstenberg in the early 2000s.7-9 As a practical solution that could fit on any waterjet cutting head, the “co-flowing helium technique” in which a stream of helium is blown parallel around the waterjet using a gas collimator (FIGURE 5) was proposed. Cadavid also considered this technique applicable for Laser MicroJet [trademarked] technology and after publication of this work, the co-flowing helium technique indeed appears to have found success in its adoption with Laser MicroJet.10System build and maintenance optimization

The Avonisys system consists of a high-pressure water pump and laser cutting head. The pump is designed to deliver a pulsation-free stream of water to the coupling assembly of the laser head with an output pressure up to 600 bar. Measuring only 65 × 42 × 50 cm, it can be flexibly fitted into CNC machine cabinets.The laser head consists of beam-delivery optics, a high-resolution nozzle alignment system, a focus z-drive, and a coupling assembly (mounted with a quick-release mechanism) with micro-alignment in the x-y plane (FIGURE 7).11 The laser window holder can be independently removed, and replacing the laser window, reinstalling the coupling assembly, and fine-aligning the nozzle is performed in under 5 minutes, while replacing a waterjet nozzle takes only 2 minutes. The ease and reliability of the setup should serve myriad customers looking to machine components with precise, kilowatt-level laser beams.

REFERENCES

1. W. Wrobel and Aesculap-Werke, patent DE3643284C2.

2. G. Delacretaz, E. Leiglon, B. Richerzhagen, E. Tasev, and LASAG, patent priority application FR9106488.

3. B. Richerzhagen, patent DE4418845C5.

4. J. Gaebelein and J. Hribar, patent US10307864B2.

5. J. Gaebelein and J. Hribar, patent US8859988B1.

6. See www.spilasers.com.

7. R. Cadavid, Cutting with fluidjets of small diameter, University of Kaiserslautern, Germany, ISBN 3936890463.

8. R. Cadavid and D. Wüstenberg, Universität 67663 Kaiserslautern, patent application DE10113475A1.

9. R. Cadavid and D. Wüstenberg, University of Kaiserslautern, Germany, 16th International Conference on Water Jetting, Aix-en-Provence, France, ISBN 1855980428, 279–286.

10. B. Richerzhagen and A. Spiegel, patent EP1833636B1.

11. J. Gaebelein and J. Hribar, patent US10022820B2.

JENS GAEBELEIN and JEROEN HRIBAR ([email protected]) are co-founders of Avonisys, Zug, Switzerland; www.avonisys.com.