Gail Kinner

From custom marking basketballs for the NBA to cutting high-performance sails for the America’s Cup, sealed CO2 lasers offer a wide range of applications to enhance a variety of sports. Here we examine several sports equipment manufacturers and uncover unique applications as well as significant cost-effective benefits for integrating CO2 lasers for custom marking and cutting.

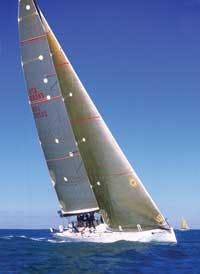

In the small town of Minden, 14 miles south of Carson City, Nevada, one would not expect to find a world-leader in high-performance sail making. In 1992, North Sails began producing the innovative 3DL (three-dimensional laminates) sail utilizing flexible composite materials uniquely layered together on very large adjustable and customizable molds. The 3DL manufacturing process is considered revolutionary. Traditional sails achieve their three-dimensional shape by sewing together multiple panels of sailcloth. There are severe limitations with this old design, because the fabric weave is either horizontal or vertical. This puts strain on the panel sail, and heavy wind loads, in all directions, can distort the fabric. North Sails’ 3DL sail, which is all one piece and customized for particular boats and uses, eliminates this problem.

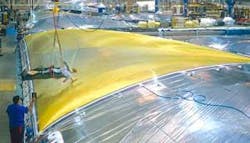

The 3DL manufacturing process begins with a three-dimensional CAD design file created by a North Sails’ designer. The custom mold file is created by identifying the sail’s desired use and optimal “fly” shape, and then the information is downloaded to the computerized mold. Because rolls of Mylar film can be found only in approximately 60-inch widths, most sails consist of 10-25 separate varying shaped and sized pieces. This material is cut and numbered using one of three 85-100ft long optical plotter beds, which house 200W sealed CO2 lasers on a gantry system.“Laser cutting, instead of traditional cutting methods, gives an improved finished edge on the Mylar and fiber base material,” states Don Hall, maintenance technician for North Sails. “The finish is cleaner and minimizes material tension.”

The laser cut pieces are then taped together, according to number, to form the custom sail shape. The assembled pieces are then laid out over the custom mold where multi-layers of fiber-based material are applied. Finally, another layer of Mylar covers the fibers and the sail is laminated using a radiant heating element. The entire production process, depending on the sail’s custom size and requirements, can take approximately 6-48 hours, which is a significant improvement over conventional panel sail production. In addition, 3DL sails can be up to 20 percent lighter than panel sails.

“The lasers we use have been running virtually maintenance free for over ten years,” says Hall. “Laser cutting the Mylar film is the only way to go. I can’t see us using anything else to do what we do.”

In April of this year, 12 yachting syndicates entered into a highly competitive boating season that will eventually determine the top team to compete against the defending champion, Team Alinghi, in the 2007 America’s Cup. To further prove the popularity of North Sails’ 3DL sails, all 12 challengers, some of which have more than one boat, will use 3DL sails during the season.

North Sails’ innovative 3DL sail technology is currently on display through October 30, 2005 at an exhibition entitled Extreme Textiles: Designing for High Performance located at the Smithsonian’s Cooper-Hewitt National Design Museum in New York City.

Ahead of the game

Spalding is well known throughout the world as a leader in manufacturing sporting goods and equipment. From footballs and basketballs to volleyballs and soccer balls, Spalding supplies the tools for top athletes, casual sports enthusiasts, and everyone in between.

The company’s idea to laser mark equipment began more than 10 years ago when customizing golf balls was popular for corporate promotions and special tournaments. Ron LaLiberty, director of product development at Spalding Division of Russell, first learned about laser marking through a local trophy engraver. “We needed to research and find the best fit for laser marking leather sports balls,” says LaLiberty. “At the time, this was the best place to start.” The idea developed into custom laser marking other sports equipment, for example leather basketballs.In the mid-1990s, Spalding was approached by the National Basketball Association to participate in Fan Fest during All-Star week by providing customized basketballs with the fan’s favorite team logo. At the time, this type of laser technology was not very portable. The entire set-up required large gas tanks, chillers, and bulky operating systems. Since that first All-Star week, Spalding has come a long way. The introduction of sealed CO2 lasers to its laser marking process almost two years ago has significantly improved cycle-time and marking flexibility. Spalding was able to integrate a 25W CO2 laser marker into a system designed by Preco Laser Systems, and cycle-time has gone from five minutes with their old system, to 90 seconds. The system enables the laser to travel between two stations. The technician monitors both stations while placing and removing each ball to be marked. This set-up is open to expansion by adding another laser, in order to have two lasers fixed on each station. Today, Spalding’s pioneering success in custom laser marking has dramatically changed the market.

“The introduction of CO2 laser technology presents opportunities to introduce products into new retail market segments that were not cost effective in the past,” says LaLiberty. “The improved engraving costs have expanded our business immensely.”

Homerun

Rally Bat, in Hampden, MA, prides itself on producing handcrafted high-quality wooden bats customized to fit every player. However, this “back to basics” approach to baseball bat manufacturing does not apply to the marking of the finished bat. When the handcrafted custom bat is complete, the laser marking begins.

In the past, Rally Bat’s method of marking finished bats involved creating a stencil, adhering the flat stencil around the barrel of the bat, and then spray-painting over the stencil. Because of the round and tapered contour of the bat, and each bat’s unique barrel size and taper, the spray paint would leak through the stencil, often producing a bad quality mark. In addition, extensive drying time was necessary if the desired mark was finally achieved. Overall, this inconsistent marking process wasted time and money.

In July 2004, Rally Bat started laser marking its bats and saw immediate improvements. Using a 25W CO2 laser marker, the company is able to custom mark coding information on each bat in 3.5 seconds, as well as a 2.5-in diameter Rally Bat logo in 8 seconds.

“With the new cycle-time and improved quality, introducing lasers has increased production dramatically,” states Rally Bat founder Jay Ray. “We are now able to customize bats for customers without extensive prep-time.”

Making waves

Motion Watersports, in Redmond, WA, supplies water skis and wakeboards to the top athletes in the world. Nearly four years ago, Motion Watersports used heat-transferred aluminum tagging for serial marking its equipment. These pre-printed labels were costly and made customizing marks impossible. Today, Motion Watersports has integrated two CO2 laser markers in order to lower production costs and improve the company’s ability to customize and track the production of its equipment.

“After one year, the lasers paid for themselves,” says Charles Mehrmann, vice president of manufacturing for Motion Watersports. “We were paying 20 cents per piece to mark equipment the old way.”

Flawed equipment can now be marked with a unique identifier after the serial number improving the classification of equipment. The finished water ski or wakeboard can also be traced back to the operator who manufactured the product, which further assists the company in tracking product manufacturing statistics and history more efficiently. In the future, Motion Watersports would like to expand on this idea and continue improving how it utilizes laser marking.

A cut above the rest

To stand out as a team, you definitely need uniforms. You also need a team emblem, and of course, numbers for each uniform. Since 1998, Integrated Laser Systems (ILSCorp) in Summerville, Georgia, has been producing finished uniforms and team clothing, as well as providing high-quality textiles and laser cutting systems for textiles. After the company spun-off from a leading European textile company, ILSCorp began building its own flatbed textile laser cutting systems, created software to support these systems, and offered a “job shop” for customers who do not have their own systems. Currently, ILSCorp has in-house six flatbed cutting systems that have 25W CO2 lasers. For highly detailed customized cuts, the power levels can easily be adjusted. For example, one of ILSCorp’s customers had a project involving an intricate design for a sweatshirt. The traditional method of constructing this design would require layering 40 separate pieces and hand-sewing the dye-cut fabric pieces together. By laser cutting the same design, not only were the cutting edges effectively sealed to prevent fraying, but also the required pieces were reduced to four.

“We revolutionized the textile industry,” states Steve Widincamp, president of Integrated Laser Systems. “Laser cutting is far superior to other forms of digital cutting, and provides cleaner finishes, is more accurate, and produces higher-quality clothing.”

ILSCorp’s laser systems have also allowed the company to be more flexible and serve a variety of markets. While many textile production jobs are going overseas, ILSCorp is able to keep many loyal customers and gradually develop new business relationships. It is currently laser cutting chemical suits for the U.S. military.

All athletes expect their equipment to be of the highest quality. This high standard is achieved and delivered by the manufacturers who use sealed CO2 lasers for custom marking and cutting sports equipment. From the general sports enthusiast to the professional athlete, CO2 laser technology creates a more affordable way for anyone to custom mark their basketball, wear their favorite team uniform, or sail like a champion.

Gail Kinner ([email protected]) is a marketing manager at Synrad, Inc., Mukilteo, WA.