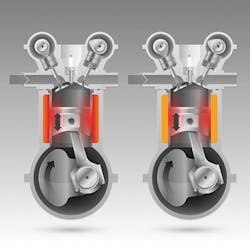

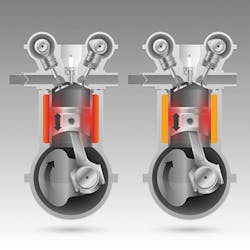

DRESDEN, GERMANY – Engineers at the Fraunhofer Institute Institute for Material and Beam Technology (Fraunhofer IWS) are using ultrashort-pulse lasers to generate very fine and friction-reducing fishbone patterns in engines, with the goal of reducing the fuel consumption of cars by more than a tenth (FIGURE).

Ultrashort laser pulses generate micropatterns in engine parts such as piston rings and thus reduce friction; the Fraunhofer IWS technology is designed to reduce wear and friction and save fuel. (Copyright: Shutterstock/Fraunhofer IWS Dresden)

Udo Klotzbach, an electrical engineer at Fraunhofer IWS involved in the work, estimates that if selected individual parts in combustion engines were treated with this process, cars could save several-percent gasoline or diesel. “If we also use it to machine plain bearings, rolling bearings, and other moving vehicle parts and calculate this for the entire car, we can even achieve savings in the double-digit percentage range,” he says. What’s more, he adds, the components last about 30% longer on average.

When the pistons in a car engine move up and down several thousand times a minute, they rub against the inner wall of the cylinder. This friction slows them down, wastes kinetic energy, and ultimately also fuel. In addition, small material losses and deformations damage the engine over time—up to the notorious “piston seizure.”

Similar friction problems arise in many machines—for example, in locomotives and milling machines. Even modern electric cars waste part of their battery charge through friction in the electric motor and other moving parts. Forecasts indicate that friction and the associated wear consume 2–7% of Germany’s annual economic output. Although friction cannot be completely avoided, however, it can be reduced. As an example, the engineering team has tested its anti-friction technologies on piston rings, which enclose the engine pistons like a seal to keep lubricating oil away from the combustion chamber.

Using lasers that emit very short, but high-energy light pulses, the engineers could generate a few micrometers of small holes on the piston rings. As a result, patterns are created that are barely perceptible to the naked eye, but look like drainage channels or fishbones under the microscope. These bone patterns have two functions: “On the one hand, they reduce the areas that can rub against the cylinder wall at all,” Klotzbach explains. “On the other hand, the channels direct the engine oil to the areas where the greatest frictional losses normally occur. In a sense, if we stick to the fishbone, its spine is the channel through which new oil flows when needed.” This causes a protective oil film to float between the ring and the inner wall of the cylinder at all times when the engine is running.

However, the laser must generate the bone pattern with high precision without producing sharp burrs. This is why the engineers are also employing ultrashort-pulse lasers, which emit light pulses that often only last 500 fs. In comparison, two trillion of these pulses are needed until a whole second has passed. “Because these pulses are so short, the material hardly heats up,” Klotzbach explains. “There are virtually no undesired effects on the material.”

In the meantime, the engineers have also developed laser speeds that allow the technology to be used in mass production. They are now testing this process together with partners from the automotive industry. They are also exploring other applications for their micropatterns—for example, in mechanical engineering and for sports equipment.

For more information, please visit www.iws.fraunhofer.de.