Historically, the biggest impact specialty optical fibers (SOFs) have made on our lives centered around telecommunications, aerospace, and industrial lasers. Every time you use the internet, your signal is routed through an erbium-doped optical fiber in an erbium-doped fiber amplifier (EDFA). Whenever you fly on a modern airliner, your journey is smoothed with stabilizing systems using fiber-optic gyroscopes (FOGs). Each time you pick up your phone and see fine detailing on metallic surfaces, you should be reminded of the ytterbium-doped optical fiber at the heart of the fiber laser used to process that surface.

What changed? The commercial and academic ecosystem around fiber-optics applications has matured—companies now have multiple generations of engineers experienced in fiber-optic applications, resulting in more rapid and robust solutions for applications that are often inefficiently served by alternative technologies.

Three emerging SOF application areas are likely to positively impact all of our lives within the near future: free-space optics (FSO) for satellite communications, fiber-optic current sensors (FOCS) for power-distribution networks, and shape-sensing crash test dummies to aid in designing better vehicle safety systems.

Bringing light to the darkness of space

If you look up at the sky on a clear evening, chances are you will see a satellite silently drifting across the sky. These were once rare events, with only 400 active satellites in orbit. Today, however, there are more than 7000 active satellites. The exponential increase in numbers was kickstarted by the new space revolution launching mega-constellations designed to deliver broadband internet and telecommunication services anywhere on the planet.

These satellites initially focused on radio-frequency transmission for ground-to-satellite and satellite-to-satellite communication, but there is now a shift to the optical domain, bringing the benefits of lower latency, higher bandwidth, improved security, and more efficient power conversion.

To achieve this, fiber-optic amplifiers are used in a similar way to EDFAs in telecom networks, boosting the attenuated signal from one node to another. The key difference is that space amplifiers require far higher signal power levels not to overcome transmission attenuation (as they are transmitting through empty space), but to overcome the resultant beam divergence from transmitting in free space over hundreds of kilometers. This results in large beam diameters of tens to hundreds of meters and, subsequently, very low coupling efficiency at the receiving satellite’s aperture. High-power fiber amplifiers are used, containing cladding-pumped optical fiber with erbium-ytterbium-doped cores in a double or, ideally for reliability, triple-cladding design.

Beyond the power level, the requirement to survive in the vacuum of space is essential. For the glass, this is a trivial matter, but for the coatings, careful selection of the right materials is required to ensure outgassing and physical changes to the coating’s optical and mechanical properties do not occur.

Cosmic radiation also presents an interesting challenge, but the scale of the challenge depends on the region of space the satellite is operating in and how the fiber is being used. Fibers have a trick up their sleeve to fight radiation: Radiation-induced damage can be partially or fully recovered through simply operating the optical fiber in a process known as photo-annealing.

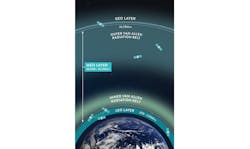

For low earth orbit satellites, which form the majority of existing and planned future satellites, the inner and outer Van Allen belts provide significant protection from cosmic radiation (see Fig. 1). When coupled with the inherent radiation shielding provided by a satellite’s mechanical structure and photo-annealing, this can result in negligible radiation impact on the optical fibers. For higher-altitude orbits, such as medium earth orbit and geostationary earth orbit, the radiation levels become more extreme, requiring optimized radiation-insensitive optical fiber designs that sacrifice optical power conversion efficiency at the start of life.

Measuring electrons with photons

On Earth, we have the urgent task of reducing energy consumption and transitioning the world to green energy sources. This brings a sharp focus on the energy- distribution networks to accurately measure electricity usage in real time and to distribute it efficiently. The challenges for networks are growing fast as large-scale, unpredictable, renewable energy sources such as wind and solar farms come online and small-scale household solar systems grow ever more popular. Urbanization and the growth of mega cities also applies pressure with the need to scale up power handling while retrofitting into existing infrastructure.

Optical fibers are often stated as immune to electromagnetic interference, but this is not entirely true. The magnetic field generated by electrical current passing along a wire can rotate the polarization state of light which is known as the Verdet effect. By wrapping an optical fiber around an electrical wire, the Verdet effect can be harnessed and used to measure electrical current. The idea is wonderfully simplistic but, as always, the devil is in the details. Any vibration or thermal fluctuation can affect the polarization state along the fiber, so the polarization requires isolation from these effects, but must still maintain sensitivity to the field-induced rotation.

This requires a unique fiber—a spun-highly birefringent (SHB) fiber—that on a micro scale is a polarization-maintaining fiber, but on a macro scale is a net zero birefringence fiber. While manufacturing the fiber, the glass preform is spun to create a constant rotation of the polarization axis, so that one full rotation is made every few millimeters along the fiber. This creates a structure that allows circular polarization to be maintained despite mechanical stresses on the fiber, but still allows sensitivity to the Verdet effect.

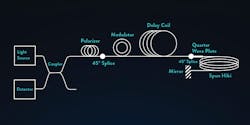

The requirement for stable circular polarization input into the sensor arm cascades a need for a chain of preceding polarization control fibers in the form of quarter waveplates, polarization-maintaining delay coils, modulator fibers, and all-fiber polarizing ZING fibers (see Fig. 2). With careful control and optimization of each element in the chain, outstanding sensitivity and accuracy can be achieved.FOCS are used throughout the Chinese national power-distribution network and are now starting to break out into the wider global market. The fiber-optic approach to current sensing offers advantages over electrical sensors: the lack of electrically conductive material in the sensor removes the need for large-scale electrical isolation, resulting in improved long-term safety and smaller sensor heads. The sensor head can be remotely operated from the interrogation equipment and, most importantly, the cost of such a system does not ratchet up aggressively for higher voltage or current applications (unlike competitive technologies).

These features make FOCS suitable for both retrofitting into existing infrastructure as well as being designed in from the start. As the world transitions toward a low carbon future, not only will the way we generate energy change but the way we consume it will too. Electric vehicles will change the load curve on power networks, requiring an evolution of existing systems and creating further opportunities for FOCS.

Smart dummies

Along with the revolutions in space and energy, we are seeing a huge disruption in the vehicle market with self-driving vehicles becoming a reality.

Developers of automated vehicles are aspiring to achieve Level 5 automation, so a human is not required for dynamic driving tasks and there is no need for steering wheels or pedals. Removing them gives carte blanche to vehicle cockpit designers, where comfort and aesthetics will take precedence over the function of driving the vehicle—but safety must be maintained for the occupants.

Crash test dummies, more technically known as anthropomorphic test devices (ATDs), have historically been loaded with electrical sensors to monitor controlled crashes to aid vehicle designs, but there are limitations to the number of sensors because of the cumulative size and weight impacting the ATD’s function.

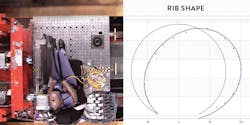

Optical fibers are now being introduced into ATDs to enable significantly higher sensor density. With the higher levels of data obtained from the fiber-optic sensors, new opportunities are being created to use the data in more imaginative ways, such as reconstructing the shape of the ATD. Figure 3 shows the analysis of fiber Bragg grating strain sensors used on an ATD’s rib to reconstruct the shape during a crash.As fully automated vehicles may allow occupants to be inside the vehicle in almost any orientation, higher-fidelity sensing systems such as this will be essential to maintain the continual pursuit of ever-increasing safety standards.

Final word

Behind the scenes, SOFs are having a progressively greater impact on all our lives. At some point in the future, it is likely you will have the chance to be driven to a remote location with full internet coverage in an automated electric vehicle, all thanks to SOFs.