Fiber-optic sensors that can distinguish between chemicals and liquids external to the fiber typically rely on refractive-index changes in the cladding modes of the fiber. These cladding modes are usually excited through permanent, fixed-position fiber Bragg gratings (FBGs) that couple light from the core mode. The excitation of cladding modes is monitored by loss of power in the end-to-end transmission of light in the core mode. Coupling takes place at specific wavelengths of incident light, which depend, in turn, on the index of test media outside the fiber cladding.

Unfortunately, FBG sensors require special equipment to “write” the gratings into the fiber and, furthermore, can only act as point sensors at specific, predetermined locations. The research group of professor Avi Zadok at Bar-Ilan University (Ramat Gan, Israel) addresses these limitations.1 The group applies Brillouin scattering processes to induce dynamic gratings at reconfigurable short sections along the fiber. These Brillouin dynamic gratings (BDGs) do not require any permanent change in the fiber structure, can be switched on and off at will, and scanned along the fiber.

Core-launched dynamic gratings

The process is best described in two parts: the generation of BDGs by optical pump waves and their subsequent readout using an optical probe wave. Generation is due to two optical pump waves that are counterpropagating in the fiber under test. The frequencies of the two pump waves are not the same: they are detuned by approximately 10 GHz.

The propagation of the pump waves carries mechanical implications: their joint intensity is sufficient to apply a force to the fiber medium. When the difference in frequencies matches a specific value, known as the Brillouin shift in the fiber, the optical forces effectively stimulate an acoustic wave in the core of the fiber. The acoustic wave functions just like a grating—it is accompanied by periodic perturbations to the refractive index of the fiber due to the photoelastic effect. The acoustic wave therefore scatters light.

The readout part is where the cladding modes come into the picture. “Once a grating is established,” says doctoral student Gil Bashan of Bar-Ilan University, “its effect is not restricted only to light in the core mode. Just like the standard and well-known FBGs, the dynamic gratings can also couple light between core and cladding modes. In analogy to FBGs, such coupling will take place for light at very specific frequencies.” An optical probe wave of tunable frequency is launched at the dynamic grating, and the exact frequency in which coupling takes place is carefully noted. Bashan continues, “Unlike FBGs, however, we are free to conduct this experiment in any position we choose.”

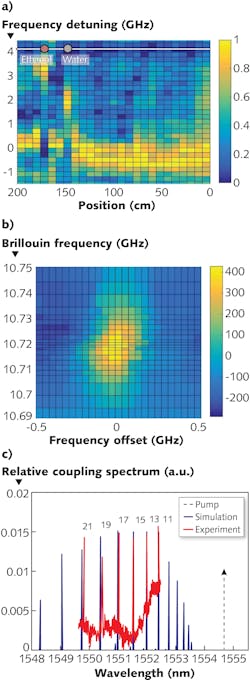

Bashan and his coworkers carried out experiments over 2 m of standard fiber (see figure). BDGs of 8 cm length were scanned along the fiber, and the coupling spectra between core and cladding modes were noted in each position. Measurements clearly identified the sections of fiber that were immersed in ethanol and water and distinguished between the two with an 8 cm resolution. The refractive index outside the fiber could be estimated with fourth-decimal-point accuracy (0.0004).

“Everything the light touches is our kingdom,” says Bashan. “Cladding modes touch the outside of the fiber. Using Brillouin dynamic gratings, we may launch these modes wherever we like.”

REFERENCE

1. G. Bashan et al., Optica, 7, 1, 85–92 (Jan. 2020).