About Us

While Cambridge Technology has always been the scanning innovator and leader, the key to our market success and growth and the resultant success of our customers has been our operating principles and mission to always be your best scanning partner - yesterday, today and in tomorrow’s emerging laser application markets.

Our company’s keys to always being your best scanning partner are:

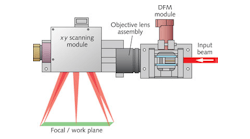

Scanning Component & Solution Innovation – Whether it’s making the smallest galvo for a hand piece, the fastest system for Via Hole drilling, powerful user friendly application software or a low cost configurations, we listen to our customer’s and the markets’ needs to enable new laser applications/markets and design the innovative products that meet those needs.

Worldwide Customer & Application Support – With our worldwide installed base across the complete range of laser applications, we have the local resources that you need to help integrate our products, whether it’s components or integrated solutions, into your system design for maximum performance. And, if the technical challenge is beyond the scope of our local resources then our R&D engineers can work with yours.

Best in Class Product Quality and Lifetimes – And, of course, after you’ve integrated our innovative products into your new system and brought it to customers and the market, then you can always depend on that Cambridge Technology consistent manufacturing product quality and lifetime that comes from our rigorous design validation and design-for-manufacturing process, our manufacturing process measurement and control, and our continuous improvement operating philosophy.

It’s a simple recipe and philosophy for our success but it’s one that we are completely focused on and committed to and one that has made us the market leader across such a broad range of scanning markets –Laser Material Processing, Laser Marking, Engraving, Drilling, Machining, Biomedical Diagnostics and Treatment, Ophthalmology, DNA Sequencing, Vision Correction, OCT, Confocal and Multi-Photon Microscopy, Industrial Laser Projection, Digital Radiography, and any other application requiring precision laser beam steering.

Committed to Innovation, Customer Satisfaction and Quality