Mainz, Germany - A consortium of companies and research institutes spanning Europe are creating an EC-funded research project to develop affordable high-power direct-diode laser systems with dramatically improved brilliance for metal laser cutting and welding applications.

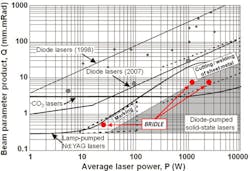

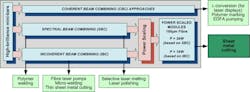

The project, code-named "BRIDLE," seeks to develop novel diode-laser minibars with 2-3× higher brilliance (~7 W @ 0.8-1.5 mm.mrad) than commercially available broad-area emitters, and spectral beam combining to further increase the total brilliance by 30-40×. The approach will be modular, scalable, and upward-compatible, according to the group, leading to a diode laser source that delivers more than 2 kW output power from a Θ100 μm, NA<0.15 optical fiber with a power conversion efficiency exceeding 40%. Different demonstrators with increasing brilliance will be developed targeting specific industrial applications.

Direct-diode lasers are seen by many as the future of industrial lasers. Laserline, and startups TeraDiode and DirectPhotonics are among the suppliers working in this area.

At this year's Fabtech in November, TeraDiode told ILS that it expects beta shipments of its 2 kW TeraBlade 2000 to multiple customers, including commercial ones, in 1Q13. Sources tell ILS that TeraDiode's system will ship with better specs than what the BRIDLE project aims to achieve. ILS also hears that DirectPhotonics is awaiting finality on a purchase order for its own high-power direct-diode system, possibly by the end of this year.

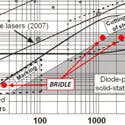

Typical beam parameters for different laser systems and materials processing applications. Some performance targets of the different BRIDLE modules are also marked. (Source: BRIDLE)

Other aspects being investigated within the BRIDLE project:

- Dense and coarse spectral multiplexing schemes, for power scaling.

- Coherent beam combining techniques to phase-couple bars, for producing nearly diffraction limited output

- External cavity phase-locking configurations (passive and active) for diode laser arrays

Several areas of work will address manufacturability and keeping system costs down:

- Simulation tools to optimize designs for the laser bars and systems; integrating optics in the minibars;

- Efficient and extremely low-vertical-divergence structures for smile-insensitive assembly and low-loss optical coupling; and

- Specific beam combining techniques and packaging (e.g. p-side down mounting, or segmented PCB on the heatsink) to allow simple fabrication and "good thermal management."

Two other deliverables include what they claim will be the first system-level design tool for high-power diode laser sources, one that "bidirectionally couples the simulation of the laser array with optical design software;" and a highly efficient and compact dense wavelength division multiplexing device, based either on volume gratings, reflective gratings, or dichroic mirrors.

BRIDLE will run for three years from Sept. 1 2012, receiving about €3M from the European Commission's FP7 Theme 3 "Information and Communication Technologies" program. It is coordinated by DILAS Diodenlaser in Germany, along with researchers from four universities -- U. of Nottingham in the UK; Fraunhofer Institute for Laser Technology (ILT) and the Ferdinand Braun Institute (FBH), both Germany; and the Laboratoire Charles Fabry of the Institut d'Optique at CNRS, France -- and industrial partners Modulight of Finland and Bystronic in Switzerland.