Initiative working towards photonics-enabled serial production

PETER JAESCHKE

An adequate use of resources is one of the biggest challenges of our times. To address this, lightweight concepts are already being adapted for the transportation industry within the automotive and aerospace sectors. To broaden the use of lightweight materials and components, there needs to be suitable processing, testing, and measuring techniques in place for a variety of materials, constituting a prerequisite for economic, flexible, and automated high-volume production. In that regard, photonic technologies can provide valuable solutions.

Since the operating mode of the laser is both highly flexible as well as noncontact, and thus wear-free, it offers numerous benefits for the machining of materials, especially as an alternative to conventional processing methods that are encumbered by high tool wear. In addition, the energy input, tailored to the respective requirements, offers new possibilities for the machining of temperature-sensitive composite structures.

In supporting measures within the framework of the Photonics Research Germany program, the German Federal Ministry of Education and Research (BMBF; Bonn, Germany) is aiming to overcome existing constraints regarding the wide use of lightweight materials in serial production. For the corresponding research and development (R&D) activities, BMBF is providing a total amount of approximately €30 million. The Photonic Processes and Tools for Resource-Efficient Lightweight Construction initiative is coordinated by Laser Zentrum Hannover (Hannover, Germany; FIGURE 1).

FIGURE 1. The Photonic Processes and Tools for Resource-Efficient Lightweight Construction initiative is supported by the Federal Ministry of Education and Research and coordinated by Laser Zentrum Hannover.

Initiative activities

Within this research initiative, nine cooperative projects under industrial leadership worked on the development of laser sources and optical components, as well as system technology and applications. In addition to welding technologies and surface preparation steps for both metallic parts and hybrid materials, laser-based processing of composites, particularly endless carbon and glass fiber-reinforced plastics, forms the core issues of the BMBF initiative.

In that respect, important R&D activities focus on composite processing, which includes cutting and drilling of resin transfer molded (RTM) parts, robotically guided three-dimensional (3D) scanning optics, and carbon fiber-reinforced plastic (CFRP) repair preparation using short-pulsed laser radiation. Further examples include composite surface preparation for adhesive applications, direct bonding, and joining of metal-metal interfaces as well as composite-metal hybrids.

In the field of laser material processing, continuous CFRP-based parts and components represent a relatively new material class, exhibiting outstanding mechanical properties at low densities. As a result, these composites have been identified to have significant potential in lightweight construction for a wide variety of industrial applications.

Addressing the challenges

Trimming, drilling, and ablation steps are of particular importance in manufacturing processes for CFRP parts. Another point is layer-by-layer removal to prepare the repair or rework of composite structures caused by fiber and matrix defects or by a missing fiber-matrix adhesion. In this context, conventional machining techniques such as milling, drilling, grinding, or abrasive waterjet cutting—which are well developed for a wide variety of established materials—suffer from high tool wear, insufficient quality, or complex setup and limited flexibility when it comes to the requirements of CFRP processing.

The primary reason for this is the heterogeneous composition of CFRP materials. Combining both carbon fibers, either arranged as fabrics or non-crimped fabrics with a polymer matrix that is either thermoset or thermoplastic, produces a unified material with very different individual material properties, and as a result presents a unique challenge from a material processing perspective. Furthermore, for cutting applications, both components must be processed simultaneously, which causes enormous difficulties. In this regard, processing CFRP components brings a lot of challenges.

Photonic processes can offer solutions for many of these factors, including the high flexibility and contactless, wear-free mechanism of the laser that offers advantages for processing such materials. For processing complex components or temperature-sensitive materials, locally limited and adjusted energy input offers new opportunities. However, implementation of laser-based processes in serial production requires a thorough understanding of the process and a high degree of automation, as well as consideration of environmental and occupational safety aspects.

If CFRP is processed with near-infrared lasers, carbon fibers show excellent optical absorption and heat dissipation, contrary to the matrix material. Therefore, heat dissipation away from the laser focus into the material is driven by heat conduction of the fibers. The matrix is heated indirectly by heat transfer from the fibers.

To cut CFRP, it is required to reach the melting temperature for thermoplastic matrix materials or the disintegration temperature for thermoset systems, as well as the sublimation temperature of the reinforcing carbon fibers at the same time. One solution for this problem is to use short-pulse nanosecond lasers, as it has been demonstrated within the HolQueSt3D joint research project.

Development of processes

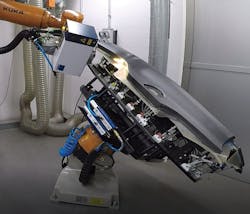

LZH has developed remote cutting processes for 3D composite structures (FIGURE 2) based on a lightweight component used in the automotive industry. A newly developed high-power disk laser from TRUMPF (Ditzingen, Germany) serves as the basic process technology—this fiber-guided laser source emits at 1030 nm and provides a maximum average output power of 1.5 kW. With a constant pulse length of 30 ns, the maximum pulse energy of 80 mJ is realized for a repetition rate of 18.8 kHz.

FIGURE 2. An example of a remote laser process for automotive CFRP components is shown.

For remote processing of an automotive part, KMS Automation (Schramburg, Germany) has designed a clamping system that addresses the specific requirements of laser processing CFRP components. One of these requirements is an integrated exhaust system for the process emissions. Processing is performed by an industrial robot system, including an additional turn-tilt table, carrying the adapted clamping device for the composite part. The robot guides the programmable focusing optics (PFO), serving as the processing head, along the cutting contour. The impact of laser processing on the characteristics of the components and on possible subsequent processes (for example, primer and painting steps) has been investigated by project partners Volkswagen (Wolfsburg, Germany) and INVENT (Braunschweig, Germany).

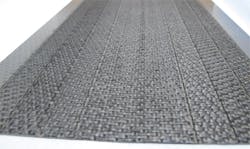

A further priority was the development of adapted repair concepts for 2D and 3D components. For this purpose, LZH developed process strategies for the scarfing of defective areas. Because of the flexible system technology, it is possible to remove large areas on complex freeform surfaces (FIGURE 3). After laser preparation, Clausthal University of Technology (Clausthal-Zellerfeld, Germany) developed repair concepts that work without hardening in autoclaves, making a more flexible and cost-efficient process possible.

FIGURE 3. Laser-based ablation of a CFRP surface for preparation of a repair process is shown.

Detection and analysis of the process emissions, as well as the development of a catalytic exhaust air treatment system matching the requirements of CFRP processing, played an important role. Based on the emission measurement during the processing, Jenoptik Automatisierungstechnik (Jena, Germany) developed a fully regenerative, continuously working exhaust air cleaning system. As the involved end user, Volkswagen supported the development of the process during the whole duration of the project and evaluated its suitability for serial production. The suitability of the developed processes was proven at the end of the project by processing an existing component used in automotive industry. ✺

ACKNOWLEDGEMENTS

The Photonic Processes and Tools for Resource-Efficient Lightweight Construction supporting measures within the framework of the Photonics Research Germany program is funded by BMBF. The author expresses his gratitude to the corresponding overall project management VDI Technologiezentrum (Dusseldorf, Germany) for their support. Furthermore, the author thanks all coordinators of the involved cooperative research projects for their engagement and their support of the coordination work, as well as all partners of the HolQueSt3D project for their excellent work in a constructive manner. ✺

PETER JAESCHKE ([email protected]) is head of the Composites Group at Laser Zentrum Hannover (LZH), Hannover, Germany; www.lzh.de.