A new horizon for advanced laser processing of copper

SIMON BRITTEN and VOLKER KRAUSE

As part of the German government-funded project EffiLas, Laserline is developing the first high-power blue diode laser sources based on laser bars. In cooperation with laser bar manufacturer Osram, the established power scaling technology for the near-infrared (near-IR) wavelength is applied for the first time for the blue wavelength. This article reviews the motivation, the technology, and the first applications with a high-power blue diode laser having up to 700 W power.

Over the last few decades, continuous-wave (CW) powered laser applications have become established as a versatile tool in modern manufacturing operations, covering welding, cladding, surface treatment, hardening, brazing, cutting, and more. The shift from a scientific technology to a common production tool has been pushed by the ongoing research of new laser sources, which have continuously enabled new applications.

The first developments in high-power CW laser technology occurred before the millennium—the establishment of carbon-dioxide (CO2) lasers at 10.6 µm and diode-pumped Nd:YAG lasers at 1064 nm. CO2 lasers, however, could not be fiber-delivered and Nd:YAG systems were limited in brightness and power-scaling capability. After the millennium, the fiber laser started to emerge as a solution for high-brightness lasers that could be fiber-delivered and nowadays are a substitute for CO2 lasers in many applications.

High-reflectivity material challenges

These CW lasers are primarily working in the ~1 µm range. For example, this wavelength is suitable for processing of steel, with over 50% absorption, but is very challenging for materials such as copper, which has an absorption of <5% at 1 µm. To process these high-reflectivity materials, high laser intensity is used to create a vapor channel in the material, which increases the absorption. However, this approach limits copper processing to a deep penetration process regime, with the inherent risk of sputter occurrence and challenging control of energy deposition.

A wavelength below 500 nm is much more suitable for processing of copper, as the absorption increases strongly to over 50%. Some solid-state laser sources are available on the market in this wavelength range that are based on frequency-doubling, resulting in wavelengths of 515 and 532 nm (green spectrum). However, these laser sources rely on a process in which a crystal is converting only a fraction of the pumped laser wavelength into the target wavelength. The conversion process leads to high power losses, complex cooling requirements, and a sophisticated optical setup.

The solution to this technical challenge is addressed with additional urgency because of the close connection to the social challenge of reduction of greenhouse gas. The replacement of combustion engines with electric engines creates a vast demand for reliable processing solutions for copper, which is used in eMobility as well as in other renewable energy systems such as wind turbines.

Goals to increase processing efficiency

To address this challenge, Laserline, together with Osram and other partners, started the BlauLas project in 2016, with the goal of developing the first high-power diode laser with a blue wavelength of 450 nm.1 In contrast to other laser source concepts, the diode laser based on gallium nitride material enables the direct emission of 450 nm, without further frequency-doubling and therefore with higher energy efficiency. With a wavelength of 450 nm, an increase of processing efficiency by a factor of 20X is expected for copper material compared to a wavelength around 1 µm.

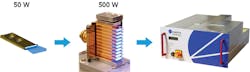

Based on long-term proven scaling techniques, Laserline uses laser bars from Osram to mount, electrically connect, and cool the blue laser bars on heat sinks. In contrast to other blue laser concepts that rely on single emitters with <5 W output power, a single diode bar is already creating a power level of up to 50 W. Using special optics, it is possible to combine several mounted diode bars in a stack and even combine two stacks in one laser source (FIGURE 1).FIGURE 1. The concept of power scaling with diode bars for the high-power blue diode laser is shown.

The success of this approach has been demonstrated with the presentation of a 700 W high-power diode laser with a beam quality of approximately 60 mm*mrad.2 The laser beam delivery to the workpiece is achieved with a 600 µm fiber and a conventional focusing optic, which is equipped with an adjusted antireflection coating to the blue wavelength. The actual ongoing project has set the goal to develop a blue high-power diode laser with over 1000 W of CW power, opening up new applications beyond copper processing.

FIGURE 2. Welding of a copper sheet with 450 nm wavelength is shown.

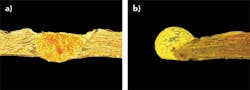

With the application of 450 nm, melting of copper material in the heat conduction mode is possible, allowing precise adjustment of the melt pool geometry for thin copper materials (FIGURE 2). The stable energy deposition and heat conduction process regime is especially important for applications in which the high pressure of a keyhole welding mode would lead to a cutting of the material or an undesirable spatter occurrence. This can occur while welding stacked thin copper foils, which may be subject to an uncontrolled gap because of warping of the stacked foils (FIGURE 3).

FIGURE 3. Cross-section of a joint between 34 stacked copper foils (each 11 µm) in butt welding (a) and edge welding configuration (b), welded with a laser power of 580 W and 2 m/min feeding velocity.

While applying a butt welding approach with 580 W laser power and 2 m/min feeding speed on stacked copper foils, a weld bead width of more than 0.8 mm can be created with minimal porosity and low undercut. For a fillet weld approach with an irradiation on the edge of the foil stack, the foil endings are melted into a high cross-section area with a complete attachment to the solid foils. In both butt and edge welding, the process results in a perfect mechanical joint as well as very good electrical conductivity.

With an outlook to more than 1 kW blue laser power and a potential to achieve a power increase together with an improvement of the beam quality, Laserline is convinced that diode lasers are going to be the leading photonic tools in medium- to high-power material processing soon.

REFERENCES

1. See https://goo.gl/KVJFnn.

2. A. Balck et al., “700 W blue fiber-coupled diode-laser emitting at 450 nm,” Proc. SPIE, 10514, 1051403 (Feb. 19, 2018).

SIMON BRITTEN ([email protected]) is in innovation management/new business development and VOLKER KRAUSE is a founder and managing director, both at Laserline, Mülheim-Karlich, Germany; www.laserline.com.