Modern automotive manufacturing uses a broad range of different materials, including plastics, metals, textiles, glass, and rubber. High-end and luxury vehicles may feature state-of-the-art carbon fiber alongside traditional materials such as wood and leather. Processing such a diverse range of materials requires a versatile tool, and this is where the carbon dioxide (CO2) laser comes in. Invented in 1964, the CO2 laser is one of the oldest laser technologies, yet it remains a mainstay of modern manufacturing and finds a plethora of uses in the automotive industry.

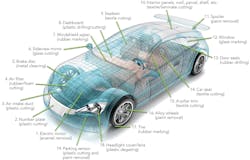

CO2 lasers are available with output powers ranging from a few tens of watts to many kilowatts, making them useful for a variety of different processes; low power levels are used primarily to mark and engrave, while higher powers can cut and weld with ease and precision. As a result, laser-processed components find their way into almost all areas of a typical vehicle, both interior and exterior (FIGURE 1).

Plastic cutting

CO2 lasers are widely used in the processing of plastic parts; these include interior and dashboard panels, pillars, bumpers, spoilers, trims, number plates, and light housings. A wide variety of plastics are used, including acrylonitrile butadiene styrene (ABS), thermoplastic polyolefin (TPO), polypropylene, polycarbonate, high-density polyethylene (HDPE), and acrylic, as well as various composites and laminates. Plastics may be bare or painted and may be combined with other materials—for example, fabric-covered interior pillars, composite or veneered trim panels, and support structures filled with carbon or glass fibers for reinforcement.

Lasers can be used to cut or drill holes for fixing points, lights, switches, parking sensors, and other components, as well as to degate or trim excess plastic left over from the injection molding process. Headlamp housings and lenses made from clear plastic often require laser trimming to remove tabs of waste plastic left after molding. Lamp parts are usually made from polycarbonate, chosen for its optical clarity, high impact/shatter resistance, and its resistance to weather and UV rays. Although the laser process leaves this particular plastic with a rough finish, the laser-cut edges are not visible once the headlight is fully assembled. Many other plastics can be cut with a high-quality finish, leaving smooth edges that don’t require post-process cleaning or further modification.

Plastic cutting operations are typically performed with laser power anywhere from 125 W upwards, depending on the time available to complete the task; the SR, SCX, and OEM series from Luxinar are all suitable for these applications. The relationship between laser power and process speed is linear for most plastics, meaning that laser power must be doubled to achieve a twofold increase in cutting speed. Handling time must also be taken into account when assessing the total cycle time for a set of operations, so that the laser power can be chosen accordingly. Of course, the handling requirements may be complex, and cutting operations frequently require either the laser beam or the part to move in three dimensions; this is where robotic technology comes into its own.

Robotics

Modern automotive production is highly automated, and robots have been commonplace throughout the industry for many years. Lasers are now used in conjunction with this technology, replacing conventional tools and bringing a host of additional benefits to the manufacturing process.

Robotic laser integration presents a unique set of challenges. There are three ways in which the laser can be integrated in robotic applications:

1. The laser is mounted directly onto the robot arm and the beam is transferred to the workpiece by a sophisticated articulated beam delivery. The robot is then programmed to cut relatively complex shapes while always keeping the beam in focus (FIGURE 2).

2. Alternatively, the robot can move the part in front of a fixed laser beam. This is a simpler mechanical process, and can be used with smaller robots, the maximum size of the components is limited.

3. An articulated arm is mounted onto the laser and the robot then moves the arm to the desired position in order to cut the parts.The first of these requires that the laser is able to withstand the G-forces produced by the motion of the robot. The robot must be large and powerful enough to support and move the laser; looking at this another way, the laser must be sufficiently compact and lightweight to allow mounting directly on the robot arm. In this respect, Luxinar’s SR series lasers are ideal. The second method often employs a galvanometer scanner to steer the laser beam as the part is offered up by the robot. Holes and small features are cut at high speed, often completing several cuts at each robot position. A typical application involves drilling small holes, typically around 1 mm in size, across the surface of an instrument panel; this allows a vacuum on the back side to remove any air voids as the cover stock is adhered to the outer surface. Larger holes and features may be cut in a similar way, for the installation of switches and sensors, for example. The larger and more powerful lasers from Luxinar are typically used in these applications.

Textile cutting

A car interior typically incorporates several different textile materials, the most obvious of which is the cloth for the upholstery. Lasers can be used to cut the fabric, and also for patterning in some cases. Process speed depends on the type and thickness of the fabric, but a laser with more power will cut at proportionally higher speed. Most synthetic fabrics are cut cleanly, and the edges are sealed so that the material does not fray during the subsequent stitching and assembly of the car seats (FIGURE 3). Leather, both real and synthetic, can be cut for car upholstery in the same way. The fabric coverings, which are often seen on the interior pillars of many consumer vehicles, are frequently finished using lasers. Fabric is bonded to these plastic parts during the molding process, requiring the excess to be removed from the edges prior to fitting in the vehicle. Again, this is a five-axis robotic process, with the cutting head following the contours of the part and trimming the fabric with precision. CO2 lasers with moderate power are typically used for these applications.Fabrics are not only for decoration and comfort; technical textiles are used in a vehicle’s safety systems, namely seat belts and airbags. Modern vehicles are typically fitted with multiple airbags as standard, to protect both the driver and passengers. Airbag materials are usually made from densely woven nylon or polyester fibers and are often silicone-coated to obtain the desired air permeability. Airbags may be flat-woven, where the bag is made up of several fabric pieces stitched together, or one-piece-woven (OPW), where the structure of the airbag is fully formed on the loom. Both types require trimming, for which a CO2 laser is the ideal tool. The laser process is efficient and reliable, minimizing waste by cutting with consistently high quality. The noncontact nature of the process means that handling of the fabric is minimized and the silicone coating is therefore less likely to incur any damage which may compromise the integrity of the airbag.

It is testament to the versatility of the CO2 laser that the same technology can be used to score lines in the material of the car dashboard and door skins, selectively weakening the structure so that a flap breaks open to release the airbag in the event of a collision. This laser scoring is implemented on the reverse side of the interior panels, so there is no aesthetic impact visible to the occupants of the vehicle; and must be performed to extremely tight tolerances.

Surface texturing

Laser processing in the automotive industry is not restricted to cutting, drilling, and trimming; in fact, CO2 laser ablation also finds several applications in automotive manufacturing. A good example is surface modification or paint removal from selected areas of plastic or composite. This is often necessary when a component is to be fixed with adhesive to a painted or lacquered surface; the top layer of paint may need to be removed or the surface may need to be roughened in order to promote good adhesion. Here, the laser is used in conjunction with a galvanometer scanner to pass the laser beam in a raster or cross-hatched pattern over the required area at high speed. The laser delivers just enough energy to ablate the surface without damaging the bulk of the material. Precise geometries can be realized with ease, ablation depth and surface texture can be controlled, and ablation patterns can be changed as required with a minimum of effort. In some cases, laser technology may replace a process previously done by hand, resulting in considerable savings in time and improvements in quality and consistency.Laser-based manufacturing is not reserved for luxury vehicles and futuristic concept cars—in fact, quite the opposite is true. A close look around any modern consumer vehicle will reveal numerous components that have been touched by a CO2 laser in some way. Perhaps security details have been marked on the windows, or information engraved into the rubber of the tires. Small drainage holes could be made in the rubber door seals, or even smaller holes drilled in the wiper blades to provide enhanced water flow during use. The brake discs may have been cleaned using an ablation process, or enamel may have been selectively removed from copper hairpins inside the motor of a hybrid or electric vehicle. Plastic parts that may have been cut or trimmed using a CO2 laser include number plates, instrument panels, door skins, lamp covers (FIGURE 4), interior pillars, filter housings, and air intake ducts, to name just a few. The CO2 laser is outstanding in its versatility, and automotive manufacturers are constantly finding new ways in which to use this well-established technology.