Using 3D printing, researchers at the Leibniz Institute for Natural Product Research and Infection Biology (Jena, Germany) have developed complex 3D poly-di-methyl-siloxane (PDMS) chips for droplet microfluidics out of 3D glass molds fabricated with FEMTOprint (Muzzano, Switzerland) technology. This direct-writing process allows sub-micrometric resolution for developing microfluidic designs with multiple levels of continuously changing heights and complex 3D shapes. Together with the simplicity of PDMS replica molding, this approach has provided an accessible solution for specialized and non-specialized labs to customize microfluidic experimentation and expand the experiment possibilities.

Related: FEMTOprint develops glass-based puncture tool for retinal vein cannulation

3D glass molds integrate the advantages of high-resolution prototyping with the ease of production and replication offered by soft lithography. It also facilitates manufacturing of multilevel structures, even with the generation of ramps (gradients of confinement), which greatly improved key droplet microfluidic operations. This technique enables novel possibilities that can be exploited not only with droplets, but in many other microfluidics applications.

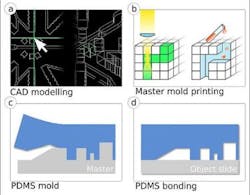

Production of a PDMS chip from 3D glass molds shows construction of the 3D CAD model (a), fabrication of a glass master mold with femtosecond laser machining (b), soft-lithographic production of a PDMS mold (blue) from the glass master mold (c), and plasma bonding of PDMS stamp to an object slide (d). (Courtesy: Leibniz Institute/M. Tovar)

The 3D glass structures present a negative part. It is also possible to bond them to glass or a PDMS slab for direct usage as chips, thus allowing utilization of structures that cannot be reproduced with replica molding (for example, microstructures in the channels or optical elements like waveguides, mirrors, filters, and lenses). Given these possibilities, chip fabrication is no longer the bottleneck for the adoption of microfluidic approaches—especially by non-microfluidic labs—but rather an opportunity for the implementation of novel functionalities. FEMTOprint technology significantly expands the experimental capabilities of the droplet microfluidic chip. It allows direct fabrication of multilevel structures such as droplet traps for prolonged observation and optical fiber integration for fluorescence detection.

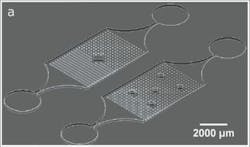

Droplet trapping chip for prolonged observation and imaging, including differently shaped chambers of variable depth. (Courtesy: Leibniz Institute/M. Tovar)

As the required gradual and/or large changes in channel depth can be easily and more precisely manufactured with this approach, the mold features 192 nozzles packed in a design measuring 25 mm long and 4 mm wide, including all inlets and outlets, generating monodisperse droplets ~70 µm. The structure can be easily scaled to contain 1000 nozzles in a 6.5 cm structure.

For more information, please visit www.leibniz-hki.de and www.femtoprint.ch.