Additive manufacturing systems supplier Optomec (Albuquerque, NM) has conducted a benchmark study demonstrating that directed energy deposition (DED) technology is 10X faster and 5X less expensive than powder bed fusion (PBF) for building mid-size metal parts.

Related: NASA awards Optomec with SBIR contract for adaptive laser sintering system

"The two most commonly used commercial methods for laser-based metal additive manufacturing technology today are PBF and powder-fed DED. Each has core strengths and can be used for similar projects. So, what we wanted to clarify with this study was when is one method better than the other,” says Lucas Brewer, LENS application development manager at Optomec. "We put both technologies to the same task and were surprised to see such dramatic differences in build time and cost. We believe this type of exercise will help customers better understand the strengths of each approach. We are always striving to help our customers improve build speed and maximize value from their machines."

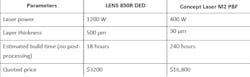

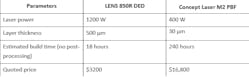

The company set out to determine the relative print speed and price to build a mid-size (150 mm in diameter, 200 mm tall) metal part made of Inconel. To establish a baseline, a part geometry was selected that could be built without support structures. Production was outsourced to two separate and independent service providers - one for PBF and one for DED. A conical shape housing with internal tubular structures was designed for this study. Quoted process parameters, build time, and the price to build the part are shown in the table.

In addition to printing time and cost savings, the equipment purchase price for Optomec LENS DED systems is less than half the cost of equivalent size PBF printers. The full details of the report are available for free.

The company's printing solutions work with the broadest spectrum of functional materials, ranging from electronic inks to structural metals and even biological matter. It has more than 300 marquee customers around the world, targeting production applications in the electronics, energy, life sciences, and aerospace industries.

For more information, please visit www.optomec.com.