The Eastern European countries Poland, Czech Republic, Romania, Slovenia, Slovakia, Livonia, Latvia, and Estonia are a part of the European Union (EU) and are deeply involved in the European scientific society. The main research and development (R&D) program is Horizon 2020, a program that is working to develop Industry 4.0 and localized additive technologies.

Belarus, Ukraine, and Russia have independent academic backgrounds and their own R&D centers. Over the last 10 years, substantial investment was made in the technological 3D printing base in universities and corporations that only found a few success stories for industrial production.

Company adoption

On March 19, 2018, SondaSys (Ogrodzieniec, Poland; www.sondasys.com) began production using stereolithography (SLA) and selective laser melting (SLM) 3D printers in cooperation with the Chinese 3D printing company ZRapid Tech (Suzhou, China; www.zero-tek.com). At the Seventh International Conference on Lasers in Medicine (held July 13-13, 2017 in Timisoara, Romania), interest was shown for new applications in medicine with laser-based additive manufacturing methods for metal-ceramic. The Transport and Telecommunication Institute (Riga, Latvia) includes in the “Research program for 2015-2020” roadmap that 3D printing is one of the most important trends for R&D and education.

The education of IT engineers for this industry has already started. Many players see huge potential in joining IT industrial platforms at companies that are producing, developing, and designing new products because this offers the possibility for efficient cooperation. Using production capacity is an open question for many companies and focuses on main advantages for every business, as it is not always necessary for companies to buy their own machines or hire specialized staff.

Russia, the biggest economy in Eastern Europe, has huge potential, but needs a lot of R&D for every application. Many of the Russian Government’s corporations have announced programs for developing industrial technologies and have invested in it—however, moving it into the industrial phase remains a challenge.

One of the metal powder suppliers to the Russian market is Polema JSC (Tula, Russia; www.polema-rus.com), which mastered production of materials for metal 3D printing in 2014. In 2018, the company commissioned and started the unique equipment stock. The project is remarkable because the company not only started production of the traditional materials for additive manufacturing, but also has the possibility for industrial production of spherical powders of refractory metals such as tungsten, molybdenum, chromium and close sizing. The research work at the company is also developing new powdered materials with unique properties that are on the way to the market. Polema sees great potential in the additive manufacturing market and presented powders for 3D printing at the Formnext 2018 trade fair (held November 13-16, 2018 in Frankfurt, Germany).

The main technology equipment producers like EOS (Krailling, Germany), SLM Solutions (Lübeck, Germany), and TRUMPF (Ditzingen, Germany) want to find the best suitable business models with local corporations and R&D partners for adaptation of their processes to local requirements.

Conmet (www.conmet.ru), an implant producer from Moscow, has its roots from worldwide titanium producer VSMPO AVISMA (Verkhnaya Salda, Russia; www.vsmpo.ru) and previous owner Tetuhin Vladislav. Conmet started with a TRUMPF machine to develop processing for production of personal implants. It is not easy to meet medical regulations for implementing new technologies everywhere. The open question is certification for using implants in daily surgical practice.

Major interest for laser additive manufacturing came from turbine and jet engine manufacturers because of the big advantages that GE (Boston, MA) brought to this business. United Engine Corporation (UEC; Moscow – www.uecrus.com) is involving R&D academic partners and investing in a program of interest in additive technologies like SLM for production and laser cladding for repairing and production. Efforts for developing processes and issues with certification for aviation need to be done before we can see printed turbine blades in aircraft. Use of ceramics for jet engine components and printing them is very positive news.

3D printing for space applications is very interesting for economic issues. The Russian Government offered several R&D grants for equipment and processes and this is still in the development phase. The same situation exists in the nuclear industry, with huge potential and regulation limitations.

The United Company RUSAL (Moscow; https://rusal.ru), the world’s second largest aluminum company by primary production output, is trying to find new markets for aluminum powder through additive technology development. Many activities are focused on business diversification with aluminum printing. The company has its own facility for aluminum powder production and the best way to commercialize aluminum powder.

Sovremennoe Oborudovanie (Solver Group; Moscow – www.solver.ru) is an integrator of solutions with additive technologies. The company business involves modernizing manufacturing companies with additive technologies. Owners and management of production companies are increasingly interested in additive technologies that are complicated enough for their own high-quality implementation. It is a big advantage in reducing production time for changing one product’s specification to another, technological and assembly operations, facilitating the designs of the parts, and assemblies being developed can be accomplished with additive technologies. Complex projects require integrators with a high level of competence in a wide range of basic and auxiliary technological processes.Best uses

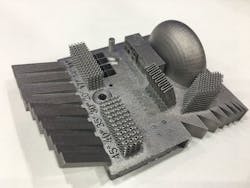

Flexibility is one of the largest advantages in 3D printing fit to Industry 4.0 paradigms. Additive technologies have almost 100% flexibility in design, so the next step is to fit them with other production processes and get more flexibility for all of them.

As an example, sheet processing technologies such as laser, water jet, plasma cutting, and punching also have a very high level of flexibility, but are limited because after cutting, many parts go to bending. Press-brake bending technology can be automated, but it is not a flexible solution due to the limitation of bending tooling and the combination of 3D printing and fully automated sheet processing running manufacturing to Industry 4.0 bending force. The idea is to move designing sheet metal products with requirements for production with flexible robotized press-brake cells. It is possible to make technological processes with a fully automated design and production chain. This production is possible because a theoretical bending model calculates all material spring-back and spring-forward for complex bending geometrics and raw material verification.

Additive technologies can be successfully integrated into production when all issues, such as processing, economics, and management, are considered. One of the main issues is production cost estimation in the development stage because it is the easiest for cost reduction. When product development is complete and it enters the production phase, it is very complicated and expensive to change production costs.

International experience shows that the best way to use 3D printing is to develop new business models and optimize it. Companies that successfully integrate additive technologies in production first find advantages in business processes. There are other ways to satisfy customers with new products or advantages, activities in universities and associations with workshops, conferences and exhibitions, and shows. In Eastern Europe, there is a huge potential for 3D printing in industrial businesses and it is one of the most attractive technologies for new business, but it needs to show how to bring the economy to another level to be effective.