Researchers at the Fraunhofer Institute for Laser Technology (Fraunhofer ILT) and IWE2 at RWTH Aachen University (both in Aachen, Germany) have developed a tiny, inexpensive mini loudspeaker, proving that microactuators can be produced in seconds and at low costs using inkjet printers and lasers. Ultra-thin piezoelectric layers fulfill actuator or sensor functions, expanding when an electric field is applied or converting mechanical motion into electrical voltage. They are in demand in communications or medical technology, for example, as sensors or actuators in pumps, valves, or loudspeakers—in each case in miniature format.

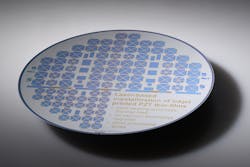

Made of lead zirconate titanate (PZT), currently the most powerful and functional piezoelectric ceramic, in layers with a thickness of a few μm they can be structured very precisely by etching or direct printing. As part of the GENERATOR project funded by the German Federal Ministry of Education and Research (BMBF), researchers developed a process combination of digital inkjet printing and laser crystallization as a favorable alternative: After PZT special ink is applied to 8” silicon wafers, crystallization follows by means of laser radiation at local temperatures of over 700°C.

A multilayer actuator was built out of several 20- to 30-nm-thick PZT layers. Alternately, a total of up to 30 layers of functional ceramics and electrodes can be built on top of each other to form a micro loudspeaker, with this actuator offering better performance and higher reproduction quality than conventional actuators. The fast laser processing of the layers reduces the processing time down to just a few seconds. The scientists used the electrically conductive ceramic lanthanum nickel oxide (LNO) as the electrode material. They can significantly increase the durability of these purely ceramic multimaterial stacks and reduce material costs at the same time.

If an AC voltage is applied to this multi-material stack, the PZT layers deform in fractions of a second, thereby exciting the entire stack to vibrate. Since the entire system is only a few µm thick and, thus, has a very low mass, acoustic signals can be transmitted excellently, especially in the high-frequency range.

Conventional systems for manufacturing thin-film electronics cost several million euros and only make financial sense for large-scale production. For smaller batch sizes, the additive hybrid process becomes attractive, especially if the component consists of several layers like the micro loudspeaker. The process is, therefore, particularly suitable for small- and medium-sized enterprises (SMEs) because their investment in the system technology turns out to be significantly less than that of conventional technology.

Until now, the process has been used to coat silicon substrates, undergoing relatively complex post-processing after the multi-stack system has been built in order to produce components that are ready for use. The properties of the laser-based manufacturing process mean that other substrates such as ultra-thin glass could also conceivably be used, an advantage that would simplify production even further and open up a wide range of possible applications. The project underlying this report was funded by the German Federal Ministry of Education and Research under grant number 03VP02223.