Cranberry Township, PA -- Westinghouse Electric says its "underwater laser beam welding" (ULBW) laser welding process, already used at nuclear plants in Japan, will make its US debut in the fall of 2013 at Progress Energy's Robinson Nuclear Plant in Hartsville, SC, to repair reactor vessel nozzles with dissimilar metal welds during the plant's scheduled outage in the fall of 2013.

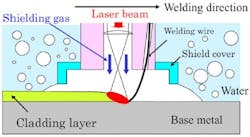

Traditional methods of underwater welding typically involve arc welding and divers, either manually or with mechanized welding equipment. The ULBW process, developed jointly by Westinghouse and parent company Toshiba, applies stress corrosion, cracking-resistant weld metal to the inside diameter surface of components, able to seal cracks up to 0.5 mm. Precise heat and dilution control of the laser beam -- low-heat input of 2.5-7.6 kJ/in, about 10% of that of standard tungsten inert gas welding -- results in consistent weld quality and high deposit purity. The laser unit can also be located up to 1000 ft away from the actual work area.

"Development of the underwater laser welding process allows us to make welds to vessel components without the customer having to drain their vessel," said Nick Liparulo, SVP of Westinghouse Nuclear Services, in a statement. "This results in a much shorter implementation schedule and dramatically reduced exposure for maintenance crews and plant personnel."

The H.B. Robinson Nuclear Generating Station, commissioned in 1971, has one Westinghouse 724MW pressurized water reactor, as well as a 177MW coal-fired unit and 11MW combustion turbine unit. It generates about 5738 gigawatt-hours (GWh) annually. About half of the world's operating nuclear power plants, and 60% of US nuclear plants, are based on Westinghouse reactors.